Manufacturing brokers

Here at Apexis Engineering we have access to a wide range of fabricators, machinists, and other specialist manufacturers.

All are trusted. All have been vetted by us. All are experts in their field.

Whether you need:

- Continuous supply of parts, machines or equipment that we’ve designed for you or

- Support for components you need manufacturing to an exact specification or

- One off items manufactured or

- A supplier of your things like spare parts for your manufacturing equipment.

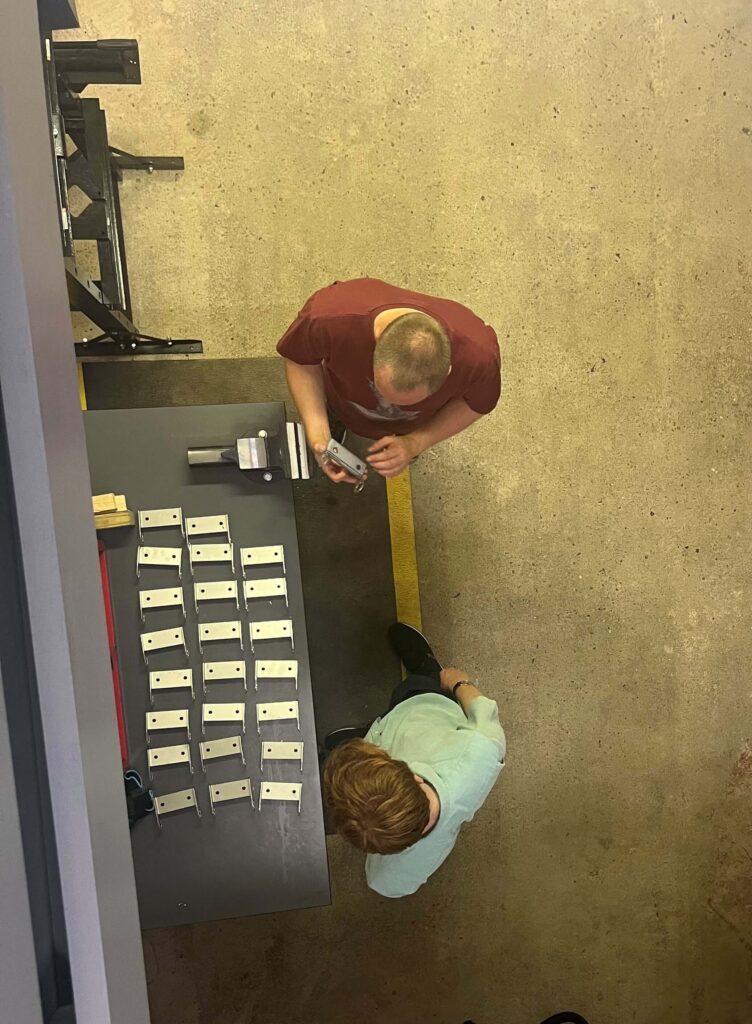

Because we are engineers you can trust that we’ll inspect everything that’s made BEFORE it’s delivered to your door.

Years of delivering engineering solutions

Projects delivered

Of all designs manufactured

Quality for one or more

Here at Apexis Engineering we can support you if you’re struggling to find a manufacturer to help you with your prototype, the parts for your existing equipment, product or machinery or need to scale up whilst maintaining quality but your supplier can’t help.

We’re one of the few companies who can pretty much guarantee everything is manufactured here in the UK whether you need 1 or 1,000 items making.

We don’t say no to helping with one offs, complex parts, unique coatings, or challenging items.

Regular supply

If you want to work with an engineering company who can bring together the manufacturing of all the components of your machine, then Apexis Engineering can help. We can find the best options for all parts and elements within your product or equipment and supply them on demand as needed.

Whether it’s large scale or small parts Apexis Engineering can handle your requirements with our wide network of experts. And what’s more we can probably help you make your product more cost effective by standardising things like bought out items and looking at the material thickness.

Engineering checks

The major benefit of working with Apexis Engineering as a manufacturing broker is knowing that we’ll complete a thorough quality check on whatever has been made for you. But we’ll also ensure we look at your drawings if you supply them or we’ll create accurate manufacturing drawings for your part at the start. This means you’ll have a full CAD model of your part or complete machine which will also help improve the quality of manufacture and ensure tolerances are set accurately.

The engineering team will also understand which supplier is best placed with the right processes, tolerances, materials, expertise, lead time and certifications for the job at hand.

Finally nothing leaves the building without us knowing it meets the specification, is of high quality and will do the job properly. That’s all part of the service.

Quote

The information we need for a quote is typically 3D models with 2D drawings with tolerances, material and finish requirements. Plus your quantities, delivery dates and any standards to be met.

Another good bit of information to share with us is the expected annual usage / requirements and any call-off patterns to help us optimise pricing and supplier choice.

FAQs

Are you accredited?

Whilst Apexis Engineering doesn’t hold ISO9001 accreditation most of our partners do. We do work in accordance with this ISO quality standard ourselves and quality is of high importance for everything we design and manufacture.

Why should we come to you if you’re a broker?

Unlike a pure broker Apexis Engineering has in-house engineering capabilities to review designs, advice on manufacturability, and manage technical risk, not just place purchase orders. This means issues can be spotted and resolved early, improving quality and reducing rework or paying for another run due to poor quality output.

Can you supply one-offs as well as larger volumes?

Yes, Apexis Engineering have set up our network to handle everything from one-off prototypes and small batches through to full production volumes. The appropriate manufacturing route and supplies will be chosen based on quantity, complexity and required lead time.

What types of parts or products can you handle?

Typically we support with machined components, fabricated assembles, sheet metal, additive manufacturing, castings and sub-assembles using our proven supplier base. We’re often asked for unusual parts, shapes, lengths or coatings and we’ve never let anyone down yet!

Do you help with design for manufacture (DfM)?

Yes we can support you with DfM support which can be as simple as quality checking existing drawings and models for manufacturiabiloity, tolerance stack-ups and cost drivers before production. Or we can undertake the full design for manufacture for your product or equipment.

Case studies

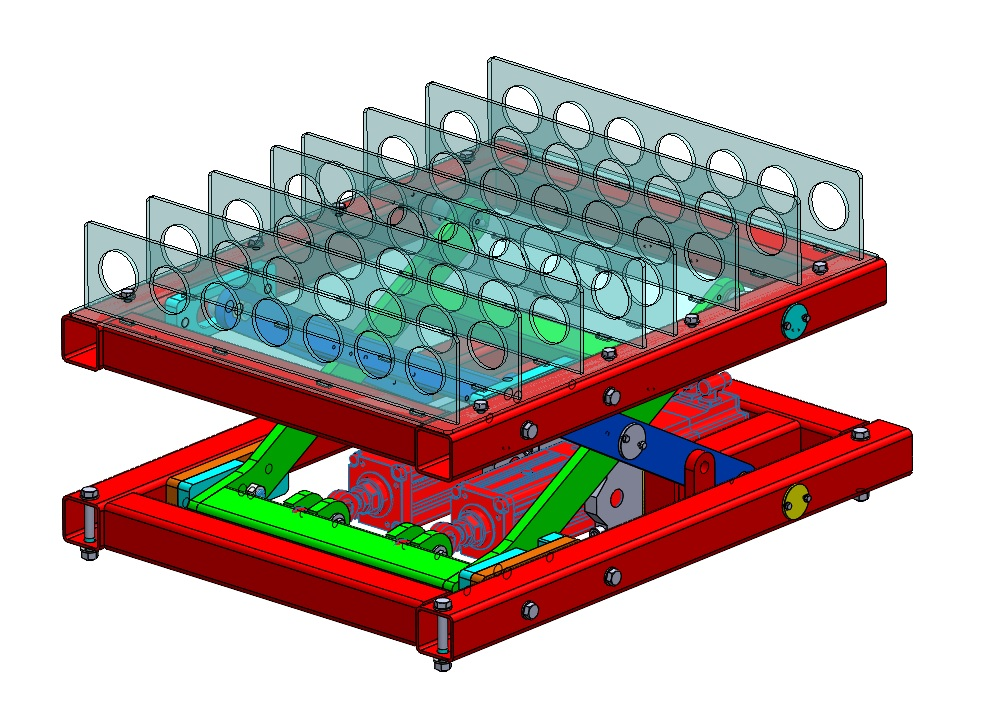

Scissor lift

Creating a robust piece of equipment that was a critical part of handling products coming off a production line

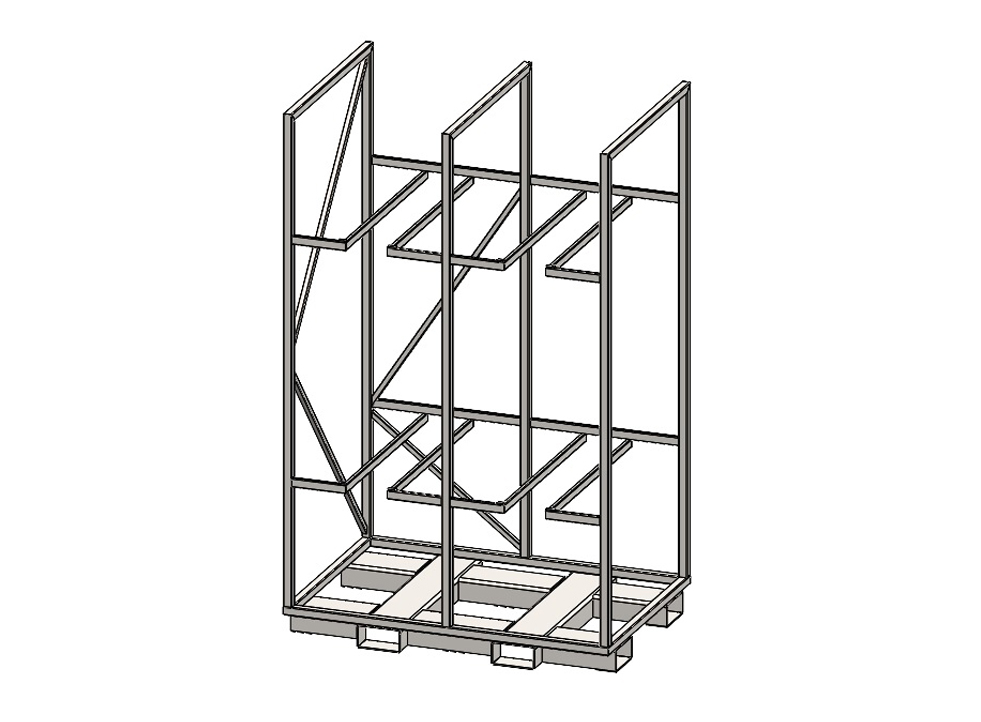

Storage solutions

From bespoke stillages to customised storage tables that are designed for the exact requirements

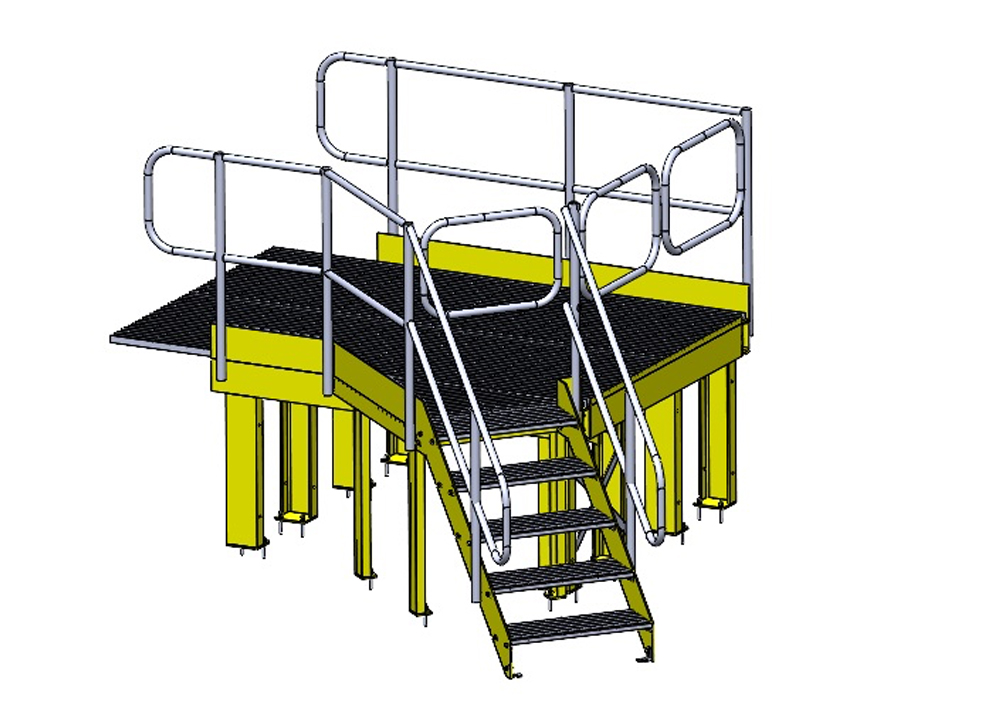

Loading platform

A bespoke platform designed for a very specific equipment handling project within water treatment

Rolling roads / chassis dynos

We are experts in the design for manufacture of rolling roads / chassis dynamometers used within the automotive industry

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.