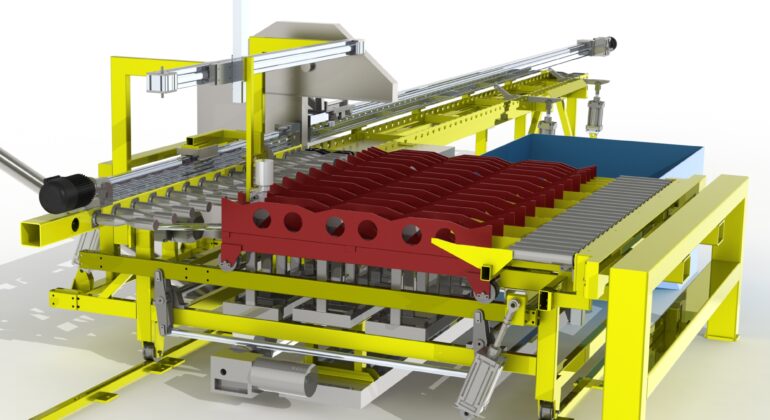

In this blog we’re going to provide the answer to this question because here at Apexis Engineering we’ve seen that when manufacturers invest with our service they can more easily drive efficiencies by having special purpose machines designed and made for their factory.

With the ever-evolving manufacturing landscape we face today a constant remains; productivity hinges on precision, speed, quality, and reliability. This is where special purpose machines or bespoke machinery makes the difference by delivering tailored solutions that go far beyond the capabilities of standard equipment.

Unlike ‘off-the-shelf’ machines, special purpose machines are engineered for a specific task or process. Whether it’s assembly, inspection, machining, or testing, these machines are designed around the exact production needs of an operation. The result is faster cycle times, reduced manual handling, and improved consistency all while lowering long-term costs and waste.

Why should you choose special purpose machines?

Manufacturers face constant pressure to improve output / throughput and maintain or improve product quality.

Here’s several key advantages on why choosing special purpose machines is a good option:

- Customised functionality – each machine is built around the unique requirements of the product, process or operating environment, ensuring optimal performance.

- Increased throughput – bespoke machinery that’s designed for true process integration will significantly raise production speed and efficiency.

- Enhanced reliability and repeatability – purpose-built systems ensure consistent performance providing options like plug and play, higher reliability, increased throughput and minimal supervision.

- Lower operational costs – Apexis Engineering always ensure bespoke machinery is designed to eliminate waste and manual inefficiencies, special purpose machines often deliver rapid ROI.

- Integration-ready design – modern special purpose machinery can be seamlessly connected to existing production lines and your PLC systems.

Special purpose machines provide a flexible, scalable investment that grows with your operations.

Specialists in bespoke machine design

Here at Apexis Engineering, designing and manufacturing special purpose machines is at the core of what we do. Our engineering team combines extensive mechanical design expertise with in-depth understanding of real-world production environments. From concept to commissioning, our process ensures each solution is functional, robust, and built with precision.

Here’s what sets Apexis Engineering apart when it comes to special purpose machinery:

- End-to-end capability – we handle everything in-house: design, prototyping, manufacture, commissioning and installation.

- Collaborative design approach – every project begins with understanding the customer’s process and pain points, ensuring the final solution fits seamlessly.

- Engineering for reliability – our machines are designed for long life under industrial conditions, using proven, high-quality components, often our parts are ‘off-the-shelf’ to ensure easy maintenance.

- Adaptable solutions – whether it’s a standalone machine or a complete production line integration, our engineers create systems that deliver measurable results.

Apexis Engineering’s track record spans sectors from automotive and food processing to precision engineering and advanced manufacturing with each project demonstrating our ability to provide creative, dependable, and cost-effective machinery solutions.

Choose Apexis Engineering to design and manufacture your special purpose machinery

If your production challenges require custom machinery, Apexis Engineering offers the insight and experience needed to design the right solution. From improving efficiency to enhancing safety and consistency, our special purpose machines help manufacturers stay competitive in an increasingly demanding industry.

Manufacturers looking for bespoke, special purpose machines need more than a standard piece of equipment, they need a partner who can design, build, install and support custom process machinery that solves a specific production challenge. At Apexis Engineering, that is exactly what is offered: bespoke process machinery, containerised (factory in a box) or skid-mounted equipment. Special purpose machines engineered around each client’s products, layout and throughput targets are all taken into consideration at the start of a project. By combining precision mechanical design with specific requirements and robust fabrication capability, Apexis Engineering delivers special purpose machinery that enhances processes, improves reliability and provides an effective, long-term solution to complex manufacturing problems.

Talk to our engineering team today to explore how a bespoke solution could transform your manufacturing performance.