Assembly jigs

Apexis Engineering have designed and supplied a number of jigs over the years for a range of purposes, uses and applications.

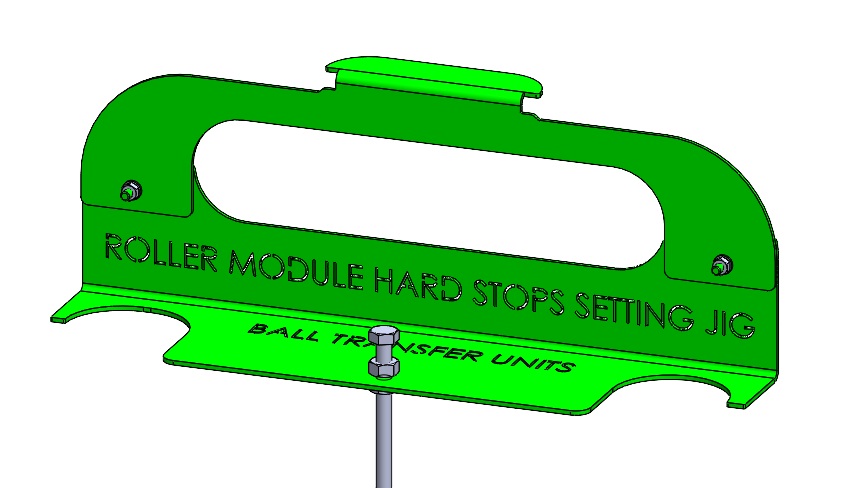

Cutting and setting jig

This customised jig needed to be used for a cutting head which had various tools in this jig enabled operators to set up offline consistently by removing the guesswork. This jig improved helped to significantly improve the product quality for this building products manufacturer.

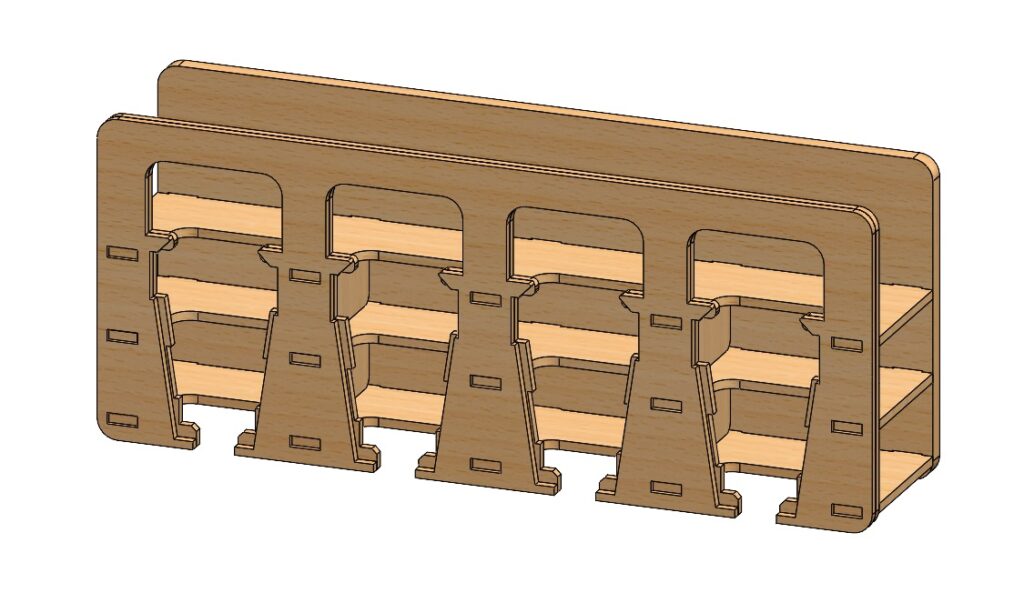

Tool assembly jig

It was important that this tool jig would not damage the finished product, so it was designed and manufactured from wood to accommodate this requirement. The jig assisted with assembling a handheld device and needed to be able to be easily taken apart for flat pack storage when not required.

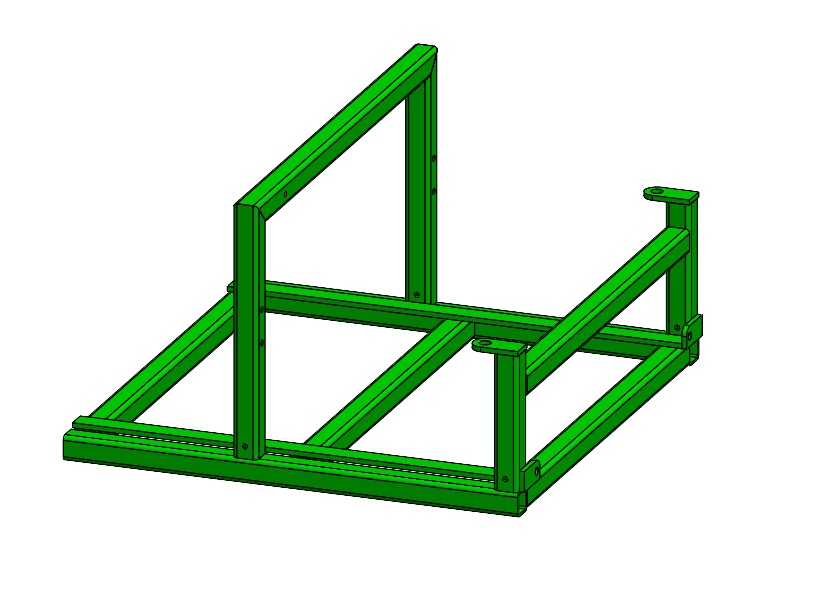

Roller module setting jig

This was a laser cut setting jig that enabled the fitters to align the hard stops on a machine when installing it. As the stops were part of a retrofit it was crucial these were aligned correctly with the existing equipment, hence the reason for a bespoke setting jig.

Quality control jig

The main requirements for this purpose designed and additive manufactured jig were precision for placing the product in to ensure it conformed to tolerances and standard. It needed to be easy to use, easy to read the scale and obvious for pass or fail for product quality. Tight tolerances on measurements / angles due to the medical products defined specification

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.