We are machine makers

We are machine makers

Starting from providing you the options to solve your challenge as concept models through to producing the detailed design and manufacturing pack for your machinery. Whether you need 1 off or 20 machines (or more!) we work with our trusted partners to manufacture your machinery. It can then be commissioned here on site or at your site with one of the team there to lend a hand or do the full installation.

Our expertise is in making the machinery work perfectly for your workplace, your operations, your products and your operators.

Tailored plant

Apexis Engineering have designed, manufacture and assembled a number of bespoke machines for manufacturers in a range of different sectors from building products to automotive manufacturers and lots more too.

Unlike off the shelf equipment, which is built for the broadest possible market, Apexis Engineering supply bespoke machinery that really address your unique requirements. Eliminating unnecessary features and optimising every detail for your workflow has huge benefits including improving quality, reducing operator hours, being safer, easy maintenance, increased throughput and efficient energy usage. Bespoke machines ensure a perfect fit, streamlining your operations and solving challenges that generic equipment simply can’t.

Years of delivering engineering solutions

Projects delivered

Of all designs manufactured

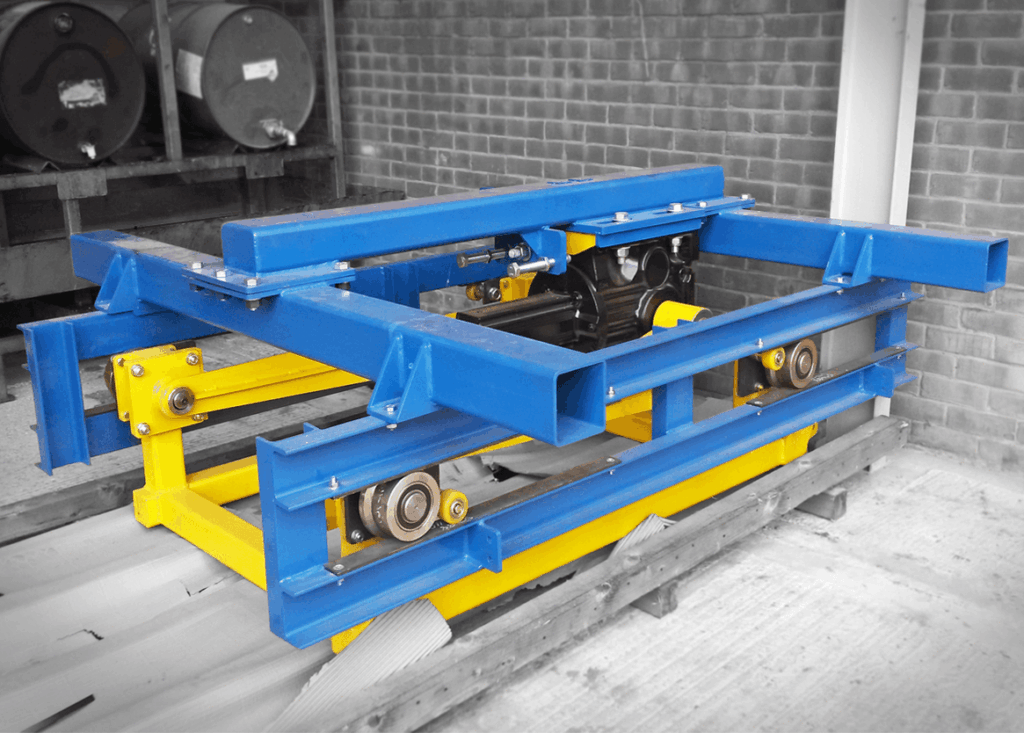

Plug and play machines

When it comes to seamless integration Apexis Engineering understand that and will take time to get to know what we need to about your existing systems and processes.

Plug-and-play machinery delivers transformative advantages for manufacturers seeking to enhance operational efficiency and maintain competitive agility. These systems dramatically reduce installation and commissioning times, allowing equipment to be integrated seamlessly into existing production lines without complex configuration procedures or extensive downtime. Manufacturers benefit from exceptional flexibility, modular components can be quickly reconfigured to accommodate different products or production requirements, making it easier to adapt to changing market demands without costly system overhauls. The simplified maintenance approach means broken components can be disconnected and replaced in minutes rather than requiring specialist engineers, significantly reducing both scheduled and unscheduled downtime costs. Apexis Engineering, we have designed a range of custom plug-and-play solutions that integrate effortlessly within operations.

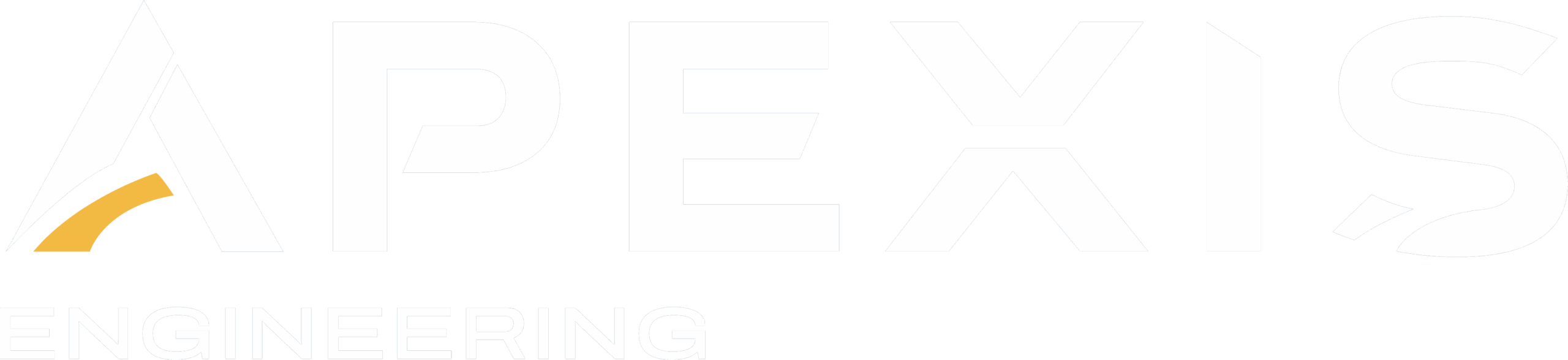

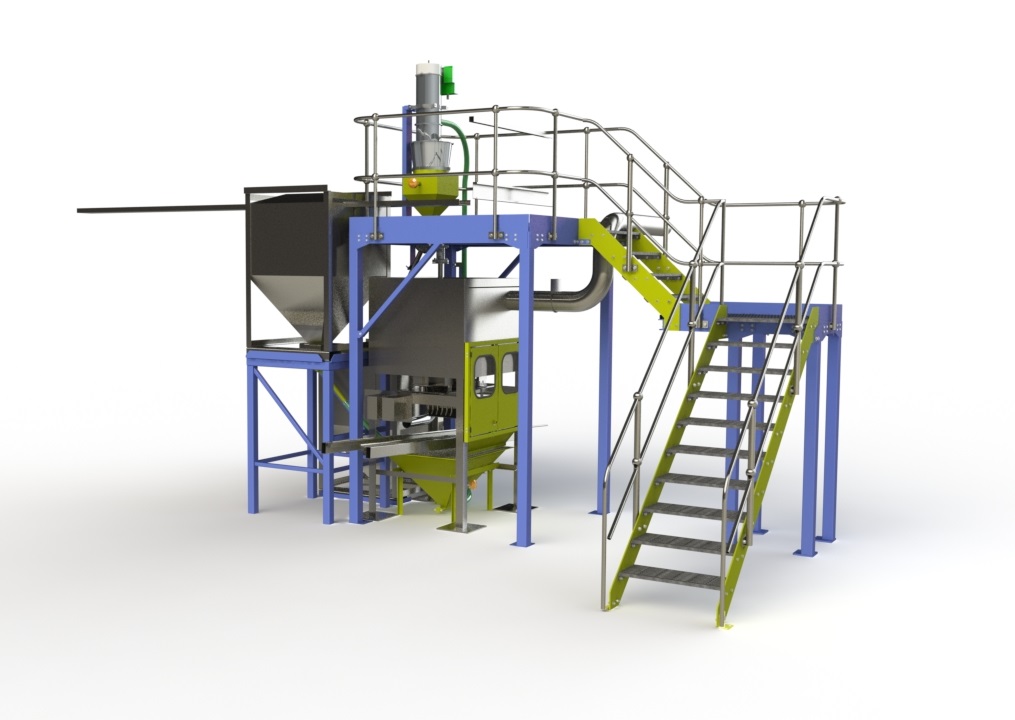

Large scale machinery

Designing and manufacturing large-scale plant and machinery as a bespoke solution has given manufacturers a system that is engineered around their process. Bespoke plant can optimise throughput, footprint, quality and energy use for a specific product mix, improving overall efficiency and reducing lifetime operating costs. Critical interfaces, from material handling to control systems, are tailored to integrate cleanly with existing lines and digital infrastructure, cutting commissioning time and de‑risking scale-up. Custom heavy machinery will always be designed with maintainability in mind with standardised spares, safe access, and modular subassemblies considered so upgrades and expansions are straightforward as demand grows. For manufacturers competing on quality and reliability, purpose-built plant and machinery becomes a strategic asset when designed and supplied by Apexis Engineering.

FAQs

What does Apexis Engineering provide when it comes to bespoke machinery?

Apexis Engineering designs, manufactures, and assembles custom machinery that fit your process, layout, and workplace, rather than forcing you to adapt to offtheshelf solutions. The team handles everything from initial concept providing 3D CAD models through to manufacturing packs, manufacture, assembly, commissioning and on-site support so your new machine works whether it is plug and play or a more complex installation.

Why should I choose bespoke machinery instead of standard equipment?

Bespoke machinery is designed around your product, throughput, quality, working environment and space constraints, which means higher efficiency, safer operation, and fewer workarounds for your team. It can also integrate cleanly with your existing lines and controls, making it easier to scale capacity, improve quality or introduce new products without major disruption.

What types of bespoke machinery can Apexis Engineering help with?

Apexis Engineering can support manufacturers with everything from one-off special-purpose machines to full processing plants, including platforms, lifting equipment, jigs, fixtures, handling systems, materials handling and automated assemblies. If it needs to move, process, or assemble something in your factory, the team can design and build a solution that fits.

Case studies

Scissor lift

Creating a robust piece of equipment that was a critical part of handling products coming off a production line

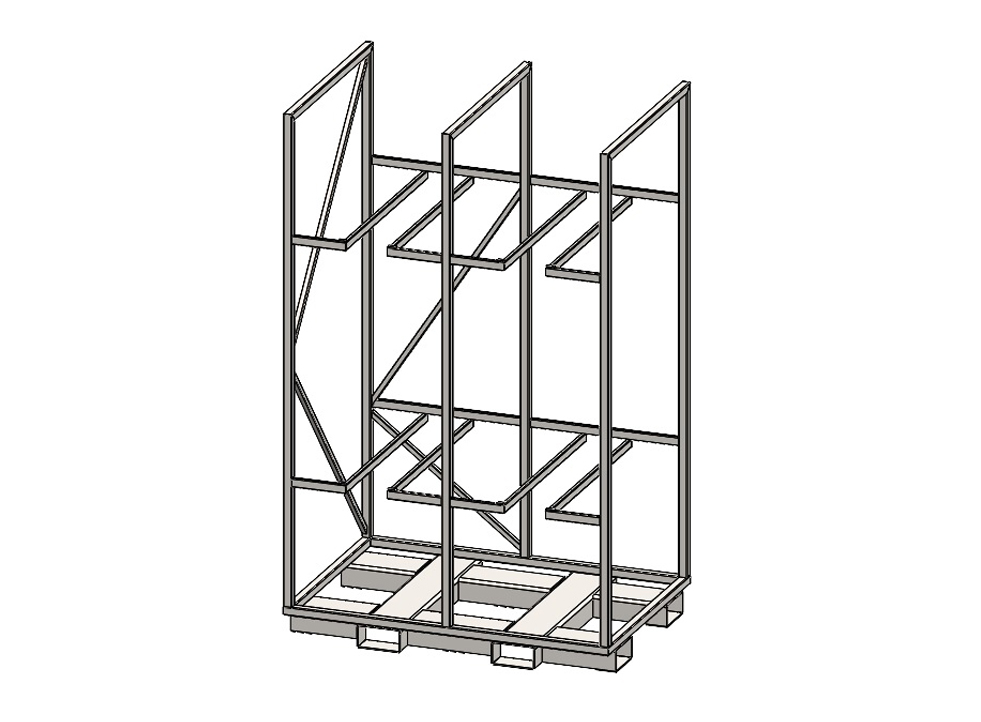

Storage solutions

From bespoke stillages to customised storage tables that are designed for the exact requirements

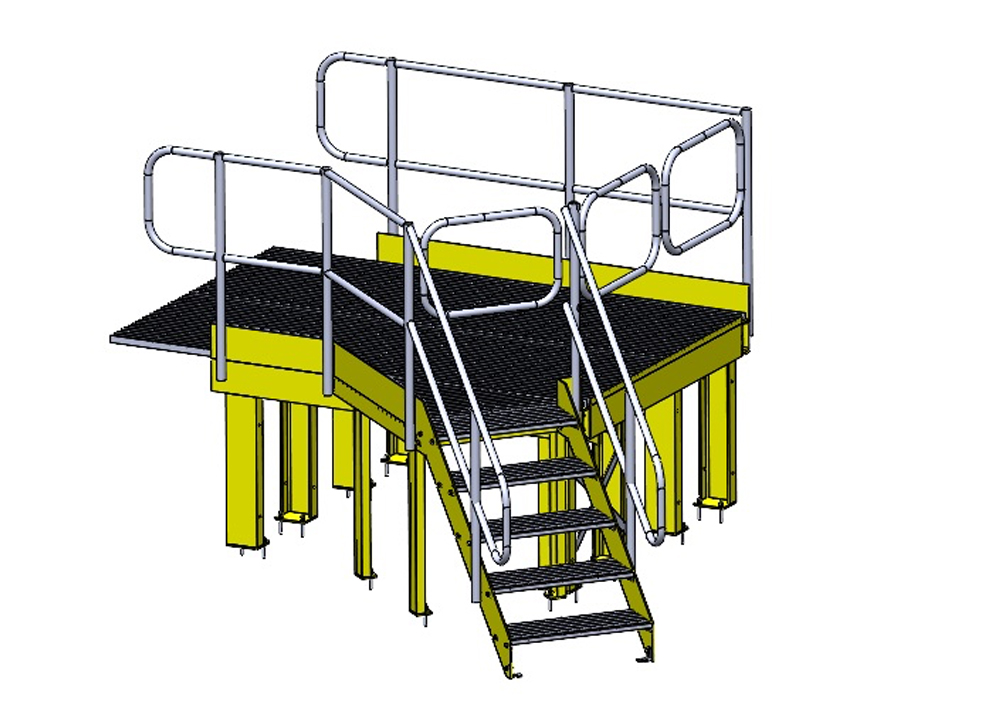

Loading platform

A bespoke platform designed for a very specific equipment handling project within water treatment

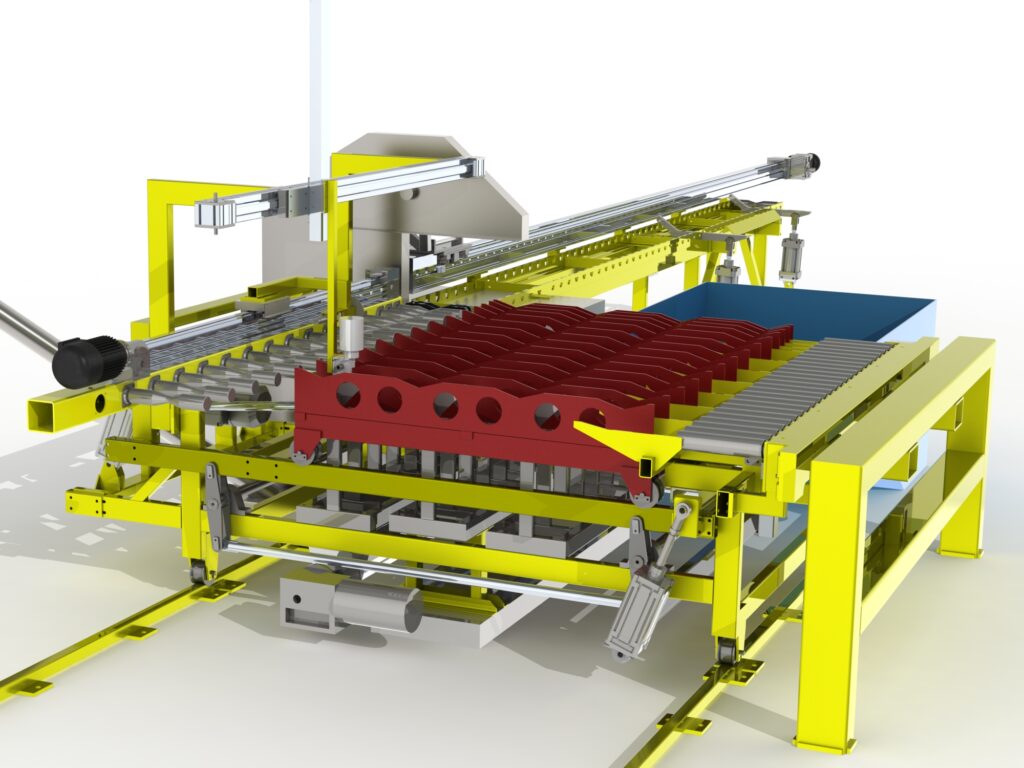

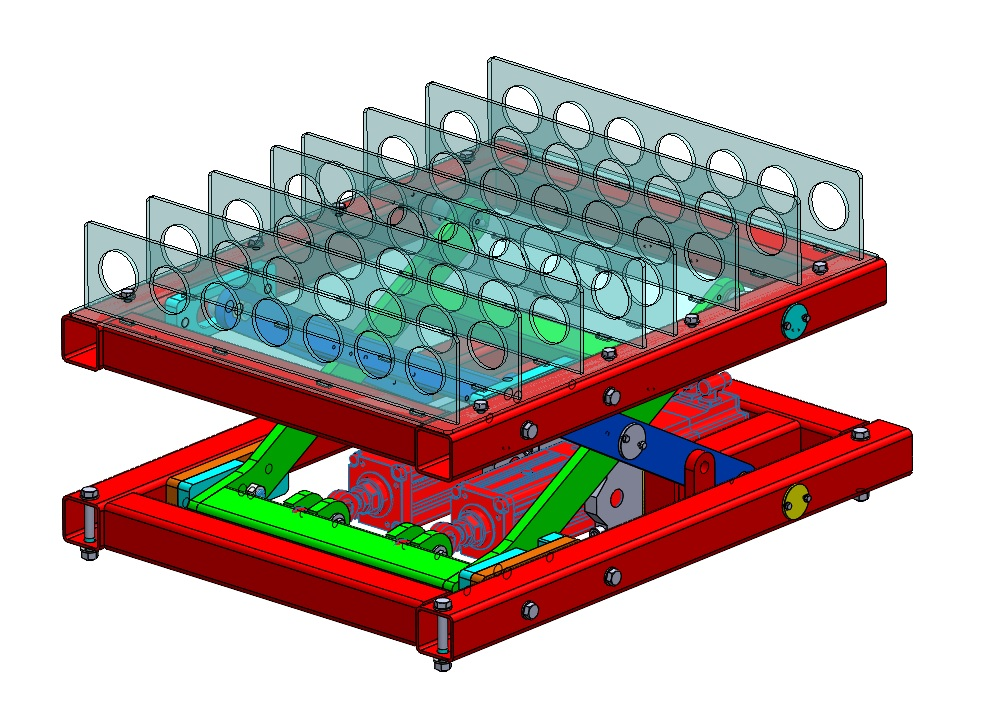

Rolling roads / chassis dynos

We are experts in the design for manufacture of rolling roads / chassis dynamometers used within the automotive industry

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.