CAD versus CAD

In this expert log we’ll walk you through CAD versus CAD to highlight why Cardboard And Drawings still matter and can be a great starting point for projects.

Let’s first be clear on the abbreviations for this article: CAD is Computer Aided Design and then there’s CAD as Cardboard And Drawings which we’ll highlight as still having a place in today’s digital world.

Project kick off

Here at Apexis Engineering we start with the right kind of CAD at the right point in the project journey; starting with Cardboard And Drawings for a concept is often the best way to get the solutions out of the engineering team’s head and reviewed. You might have spotted us in action on our whiteboard; it’s an invaluable piece of kit here! Once the concept is ready to move forward to the next stage then the computer can be fired up and the digital world of CAD entered.

Begin with Cardboard and Drawings

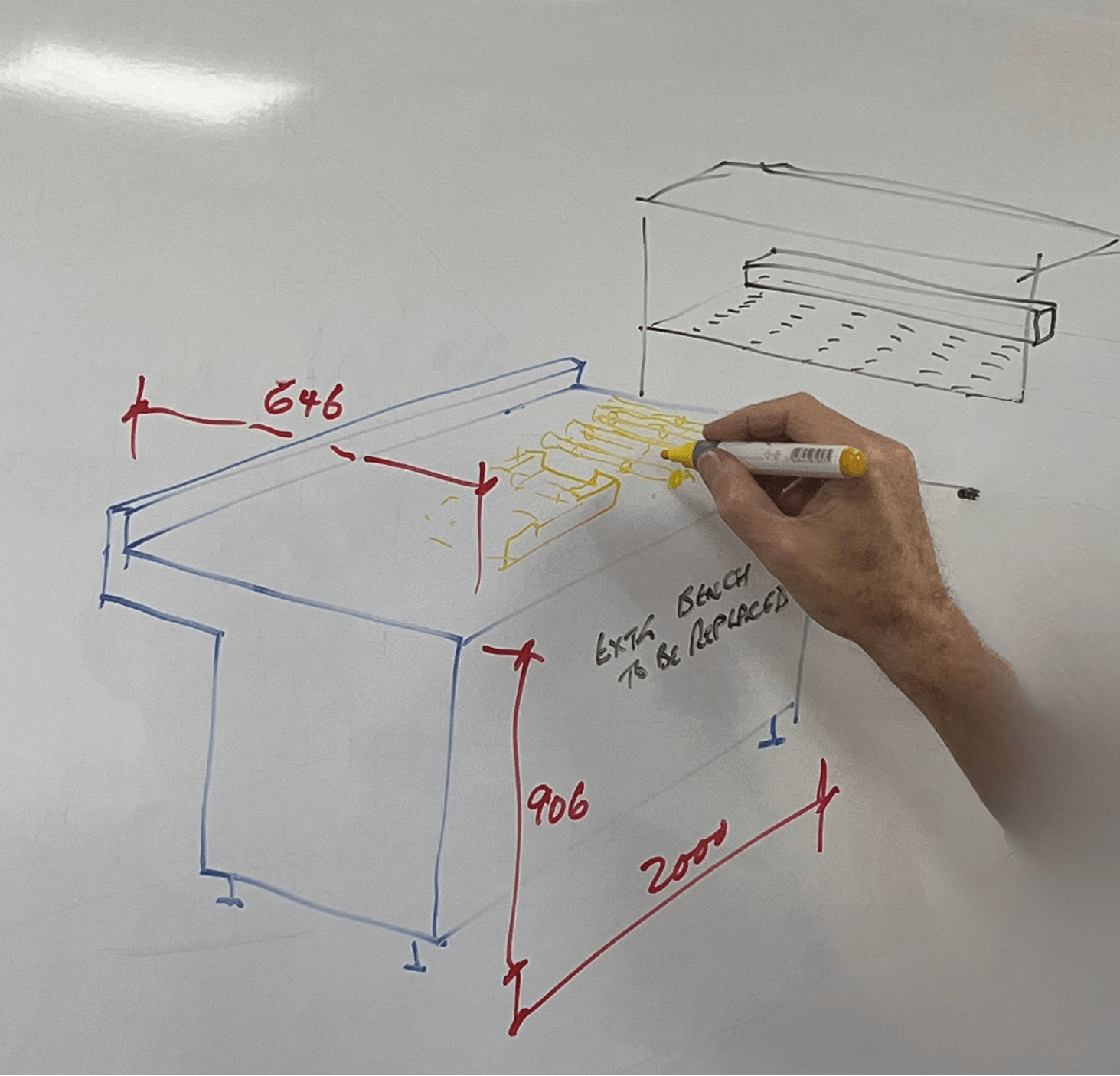

When a project starts with a concept or providing a range of options to solve the challenge the best CAD to start with is the one that is the lowest cost but biggest value and that’s hand sketches or cutting out card.

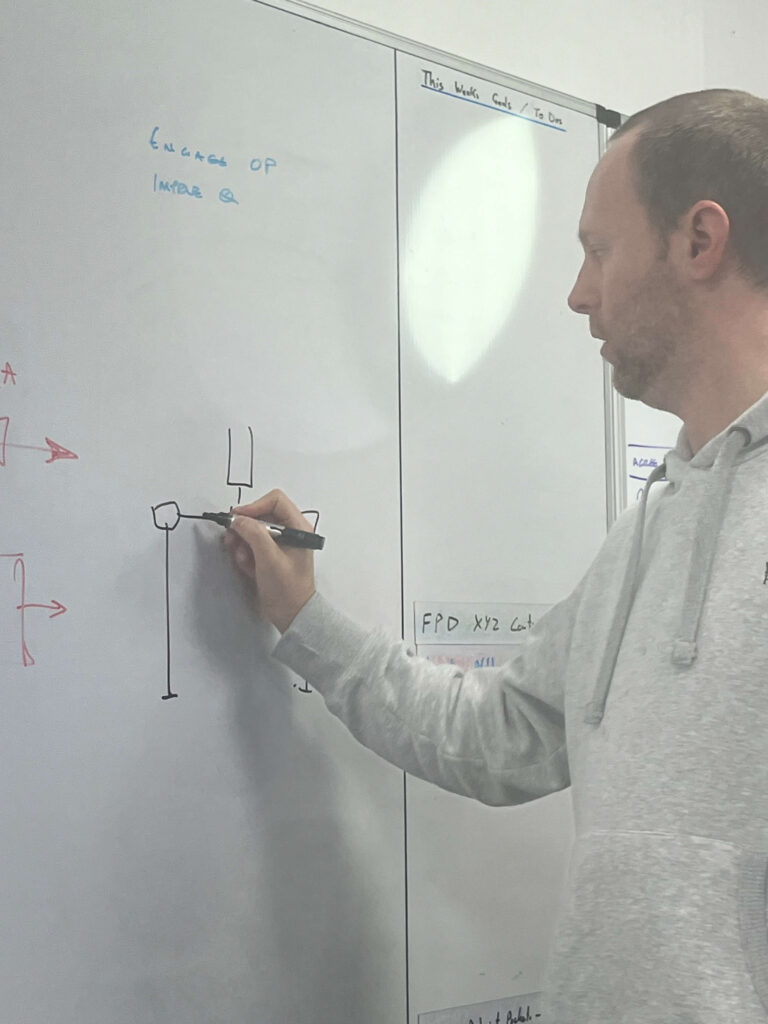

Early on in a project, the biggest risk is not a bad model, it is solving the wrong problem. A whiteboard session with the client, backed up by cardboard, tape and marker pens, forces everyone to stay focused on what must be achieved rather than how clever the design looks on the screen. Here at Apexis Engineering we might not even involve the client in this first idea generation stage with markers on the whiteboard. This stage is where requirements are challenged, assumptions are exposed and rough process flows are sketched in minutes, not days.

Working at full scale with simple materials is especially powerful for bespoke machinery and customised equipment. Our engineers will walk the production line, map operator movement, mark out machine envelopes on the floor and build quick mock-ups on the paper held on our trusty clipboards. These sketches will review showcase where an item we’re designing and making will physically occupy and the space the final solution will need or sometimes has. Interferences, awkward reaches, access issues and safety pinch-points appear immediately when we can stand inside the concept rather than just look at a screen.

Why Whiteboards beat Screens at the start

We’ve highlighted above why our design office whiteboard is so valuable. But it doesn’t just have to be our whiteboard that kicks off a project for bespoke design and manufacture projects. Whiteboards create a shared focal point for operators, maintenance teams, buyers and engineers to think together. Because nothing is precious at this stage, it is easy to wipe out an idea that won’t work, redraw a layout, or re-sequence a process without anyone worrying about “breaking the model”. That low-friction environment makes it more likely that hard questions get asked early, when changes are cheap and easy.

This style of rapid, collaborative sketching is also faster for exploring multiple options. In a single session, the Apexis Engineering team can work through alternative process flows, material paths or guarding concepts, and decide what is worth taking forward. By the end, the whiteboard often holds a clear story: inputs, outputs, critical interfaces, and the constraints any CAD model will have to respect.

Cardboard mock-ups for Bespoke Machinery and Equipment

Let’s be clear here; we’ve had clients walk into our design office with cardboard mock-ups of the machinery or equipment they’re looking for support with. And sometimes things go one further and we see a wooden mock-up (we’ve had two of those in 2025!).

For bespoke machinery and equipment, cardboard and foam-board mock-ups bridge the gap between ideas and reality. They let the team block out key modules, like feeders, tooling, guarding, services, and see how they interact at real scale. Operators can simulate use if appropriate like load parts, press imaginary buttons, mimic maintenance tasks and emergency access in three dimensions.

These quick physical trials reveal practical issues that CAD alone can hide, such as how a door actually swings in a congested area, whether a maintenance hatch can be reached with tools, or how a pallet jack will approach a conveyor. Fixing these problems while everything is held together with tape is dramatically cheaper than moving steelwork, cables and guarding after installation.

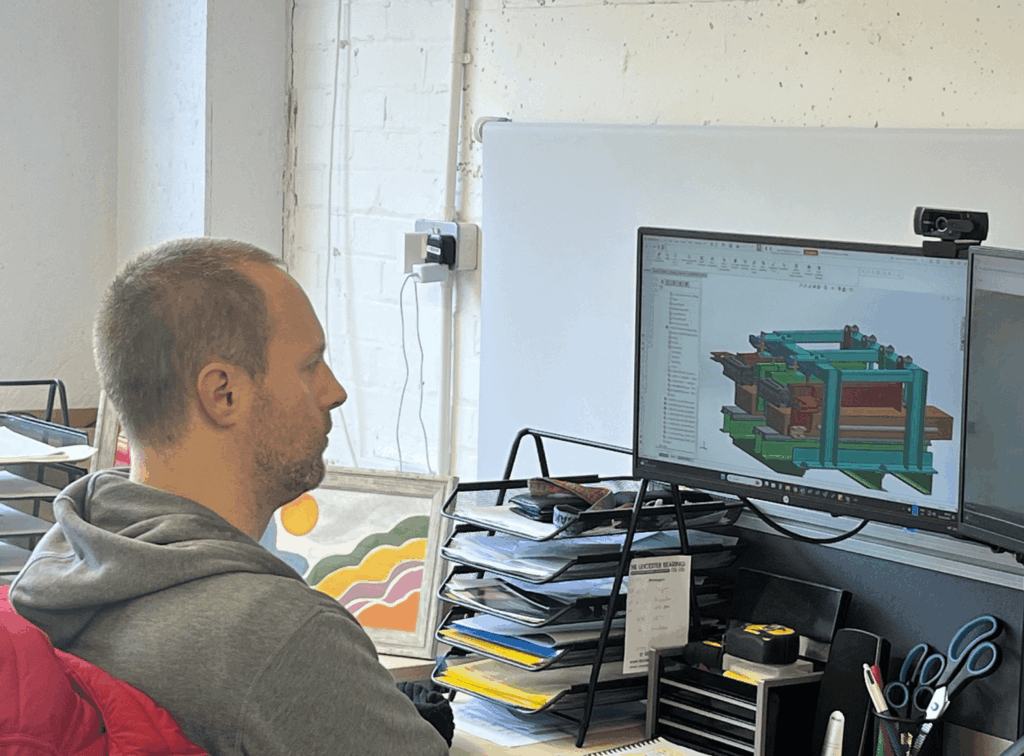

When To Move Into CAD

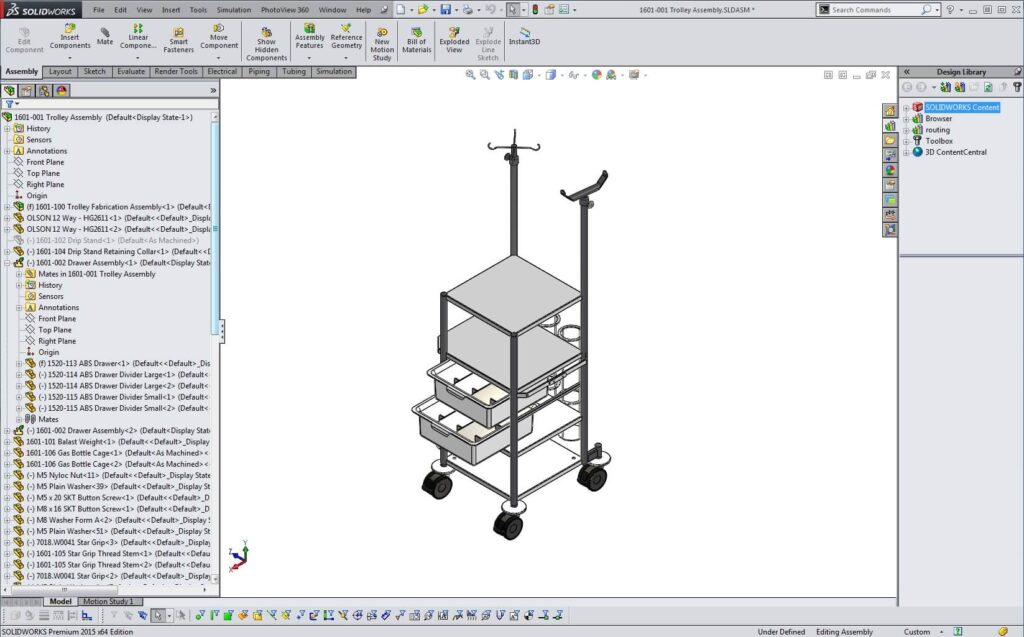

Once the whiteboard and cardboard phase has converged on a concept that works for all stakeholders, it is time to switch meaningfully into Computer Aided Design. At this point, CAD is no longer being used to guess the solution; it is being used to engineer it. The team can translate the validated layout into a robust 3D model, locking down critical dimensions, interfaces and clearances that have already been proven at full scale.

This is where CAD earns its reputation with accurate assemblies, interference checks, weight estimates, motion studies and build sequences becoming possible. The groundwork done on the board means fewer major design swings inside the CAD model, so effort is concentrated on refinement rather than rework. That leads to cleaner designs, fewer surprises and a smoother route to the design for manufacture stage.

From CAD to Prototypes and Production

With a solid CAD model in place (manufacturing pack with BOMs etc), Apexis Engineering can generate the detailed deliverables that turn a concept into a machine. Parametric assemblies feed directly into manufacturing packs: cut lists, fabrication drawings, machining models, sheet metal developments and exploded views for assembly. The same model supports virtual prototypes, finite element checks and design-for-manufacture reviews before a single component is cut.

For prototypes and one-off customised equipment, this CAD-driven stage ensures that every bespoke bracket, jig and guard will fit first time on the shop floor. We know that as we live it with the machinery and equipment we design and manufacture day in day out.

When changes emerge from commissioning and testing, controlled updates to the model keep the entire documentation set aligned. The result is a process where cardboard and hand sketched thinking at the start and digital precision at the end work together, giving clients confidence that the solution they saw on the whiteboard is the one that arrives on site.

We’ll always be advocates of bringing our clipboard with paper on site, moving to our whiteboard for idea generation then creating a CAD model for a concept that will solve the challenge perfectly.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.