Customised equipment

Apexis Engineering have designed and manufactured a range of customised equipment over the years including:

- Trolleys

- Access platforms

- Lifting equipment

- Stillages

- Storage equipment

- Assembly jigs and aids

- Stairways

Custom equipment such as platforms, lifting solutions, and jigs that are designed specifically for your site can transform both safety and productivity. By matching your exact layouts, access points, and workflows, these customised solutions minimise awkward reaches, manual handling, and working at height risks, helping teams work more safely and confidently. Purpose designed platforms and lifting aids streamline changeovers, maintenance, and inspections, cutting downtime and making it easier to keep critical assets running. Bespoke jigs built around your components also improve repeatability and ergonomics, reducing defects and operator fatigue while speeding up each task. The combination of safer access, smoother handling, and more reliable fixturing delivers a strong return on investment and a better working environment for your people.

Years of delivering engineering solutions

Projects delivered

Of all designs manufactured

Lifting equipment

Apexis Engineering can provide custom built equipment that is designed to handle unique loads, work in a range of operating environments, and offering various weight capabilities. Having your lifting equipment purpose designed and built reduces the risks of accidents, equipment failures and damage to goods by providing precise lifting capabilities tailored to your needs.

Examples of lifting equipment designed and manufactured include:

- Bespoke pallet lifter

- Bag lifting frame

- Customised lifting arm

- Special bespoke portable lifting device

- C lifting frame.

Assembly jigs and aids

Having bespoke assembly jigs designed and manufactured for your operations brings significant benefits in terms of safety, quality, efficiency and precision.

We find that bespoke jigs enhance productivity by streamlining workflows, improving repeatability and reducing assembly time. When we have designed jigs for clients we have seen higher quality output and a reduction in errors when in used.

Examples of assembly jigs and aids Apexis Engineering have supplied include:

- Jib crane to improve site safety

- Frame assembly jig

- Cutting and setting jig

- Lifting beam for 10 tonne equipment manoeuvring

- Tool assembly jig

- Roller module setting jig

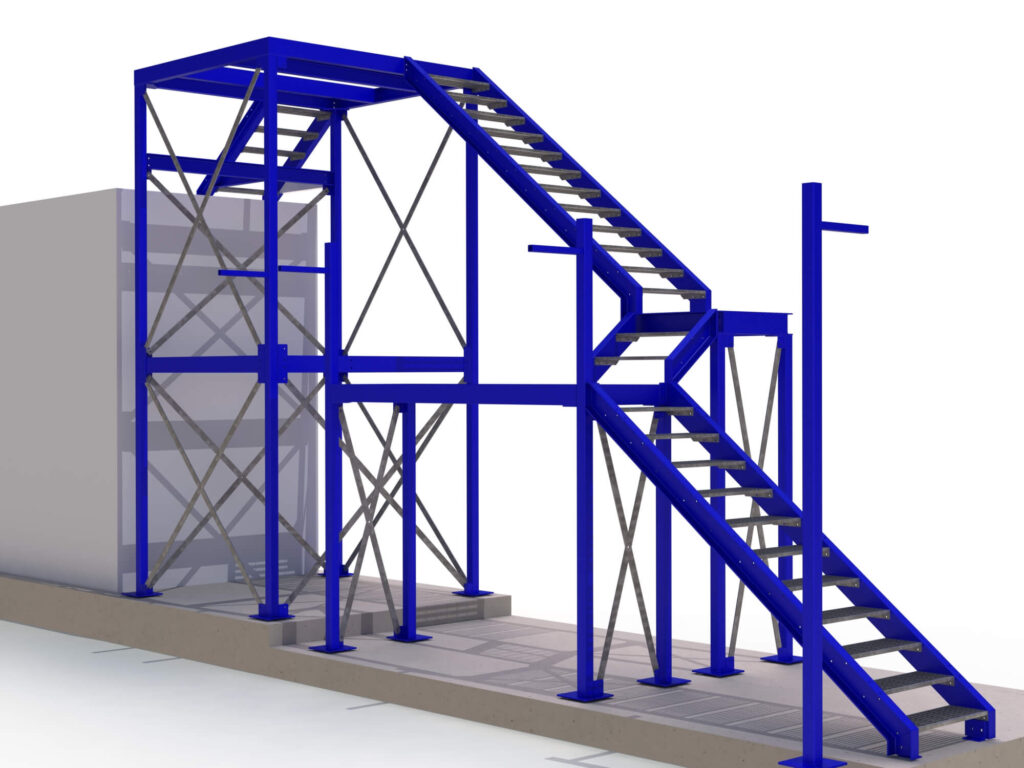

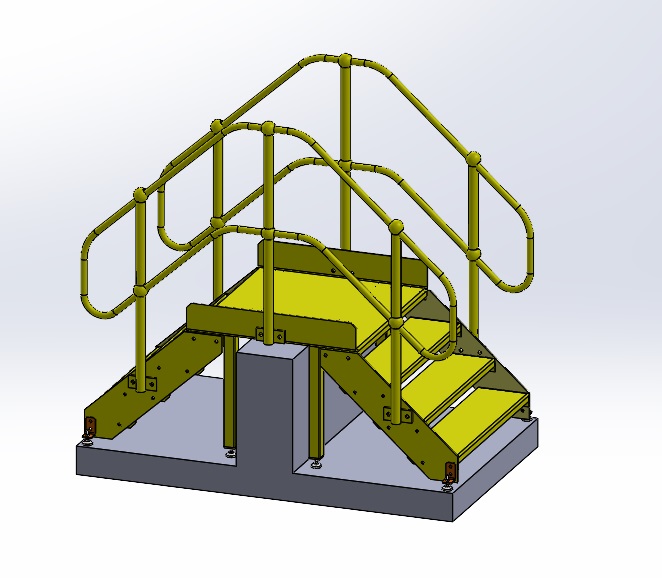

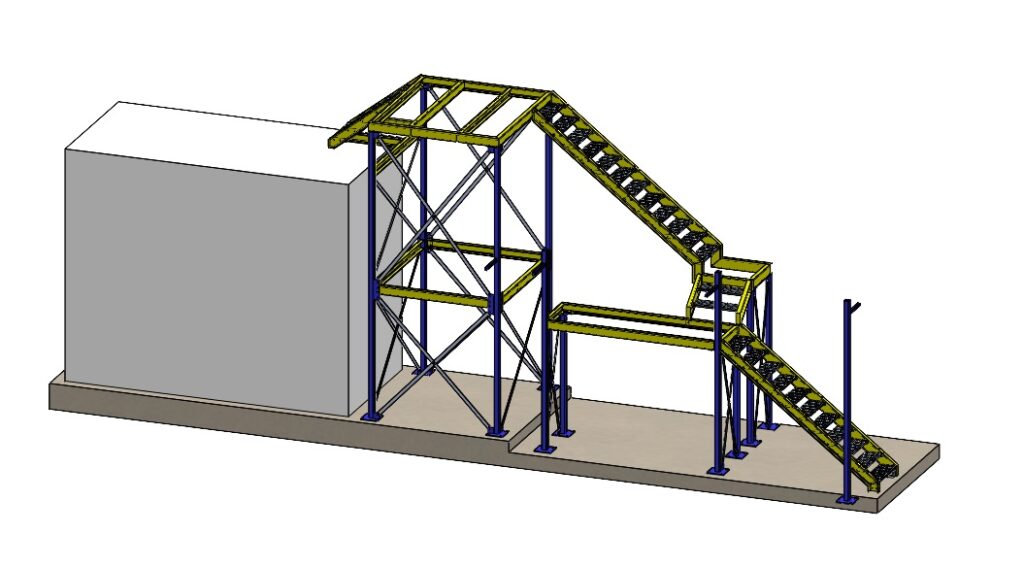

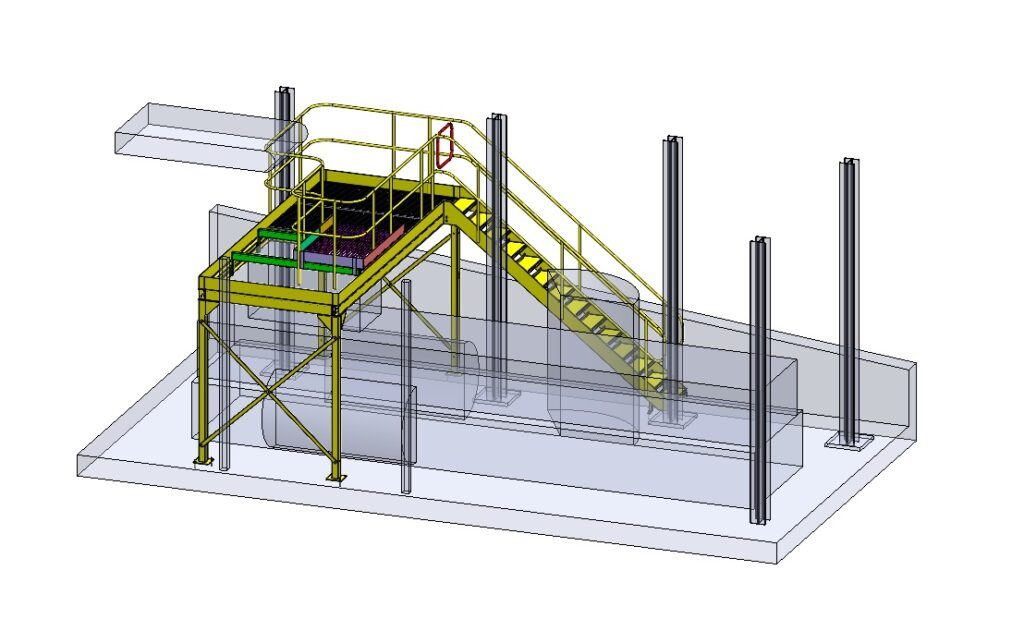

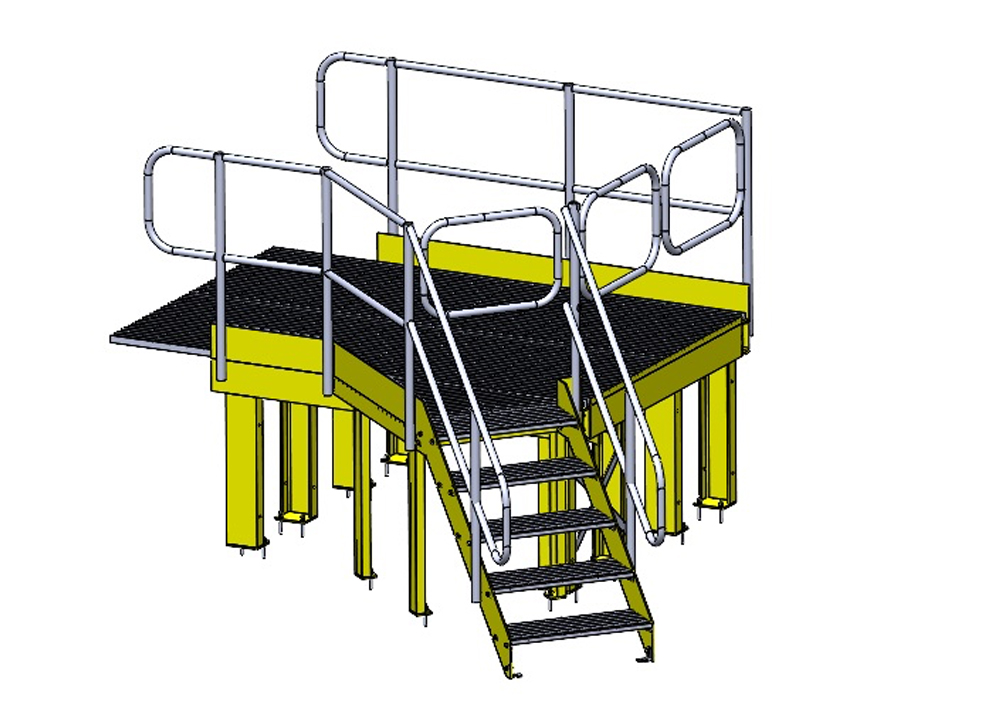

Access platforms

Over the years Apexis Engineering have designed, manufactured and installed a range of fixed access platforms and mobile options into a range of settings. Having bespoke platforms designed for your workplace ensures a safe working environment with the perfect height, load capacity and right configuration for your daily tasks whatever they are. We design platforms specifically for your site and operations whether for the maintenance team, the operators or the warehouse staff to work more efficiently, compliantly or safely.

Every platform Apexis Engineering delivers will confirm to all the relevant British Standards and will have installation considerations for bringing the platform into a building.

Examples of projects we’ve completed include:

- Fixed access platform for improved plant maintenance

- Effluent system platform

- 50 tonne platform for a major infrastructure project

- Loading platform for handling equipment

- Industrial stairway for gantry access within a manufacturing setting

- Platform and stairways within a food manufacturing plant with specialist cleaning requirements

FAQs

How will “custom industrial equipment” be helpful on my site?

If you know you need access or maintenance platforms, lifting equipment, jigs, storage solutions, and handling trolleys it’s a good idea to get things designed specifically around your layout, products, and processes, rather than trying to make generic equipment fit. The result of choosing customised equipment is that feels “made for the job”, is safer to use, and supports the way your team really works instead of them finding an (often unsafe) work around.

Why not just buy standard trolleys, racks, or platforms?

Standard items rarely line up perfectly with your clearances, load sizes, workplace layout, and handling routes, which leads to awkward workarounds, wasted space, and more manual handling happening than is necessary. Custom equipment is optimised for your dimensions, weights, and flows, so you move more product with less effort and far less risk.

How can custom lifting equipment and access platforms improve safety?

They are designed around real access points, service tasks, and operator reach, so people can work at the right height with proper guarding, handrails, and anchor points. That reduces work-at-height risks, twisting and overreaching, and makes inspections and maintenance quicker and safer. Everything Apexis Engineering designs and manufacturers will come with an FEA report to understand safe working loads and conditions.

Case studies

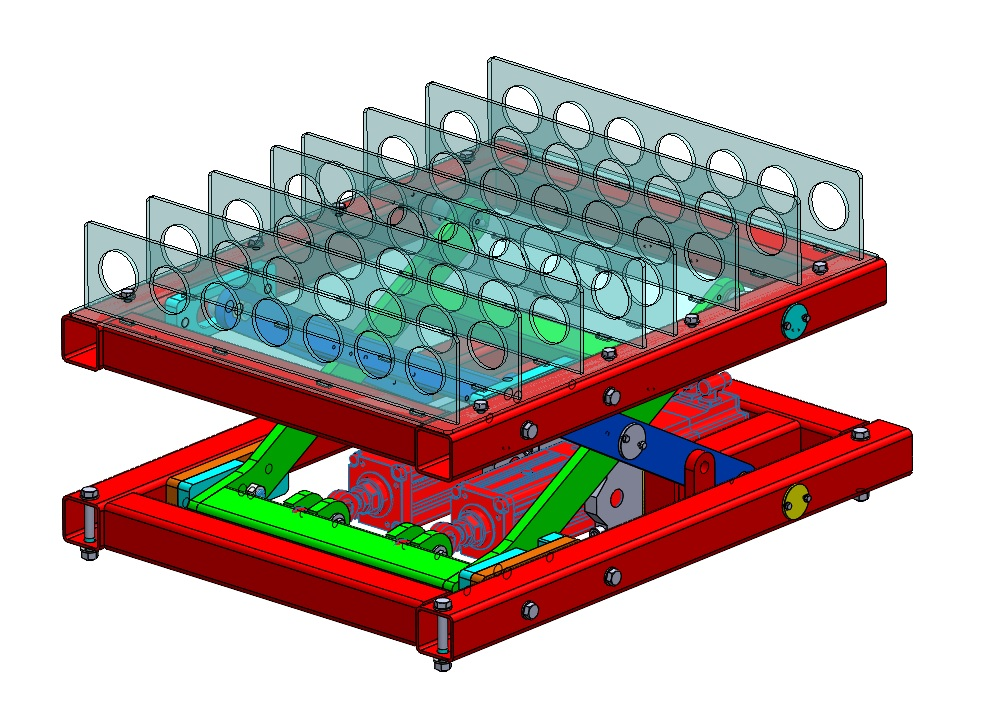

Scissor lift

Creating a robust piece of equipment that was a critical part of handling products coming off a production line

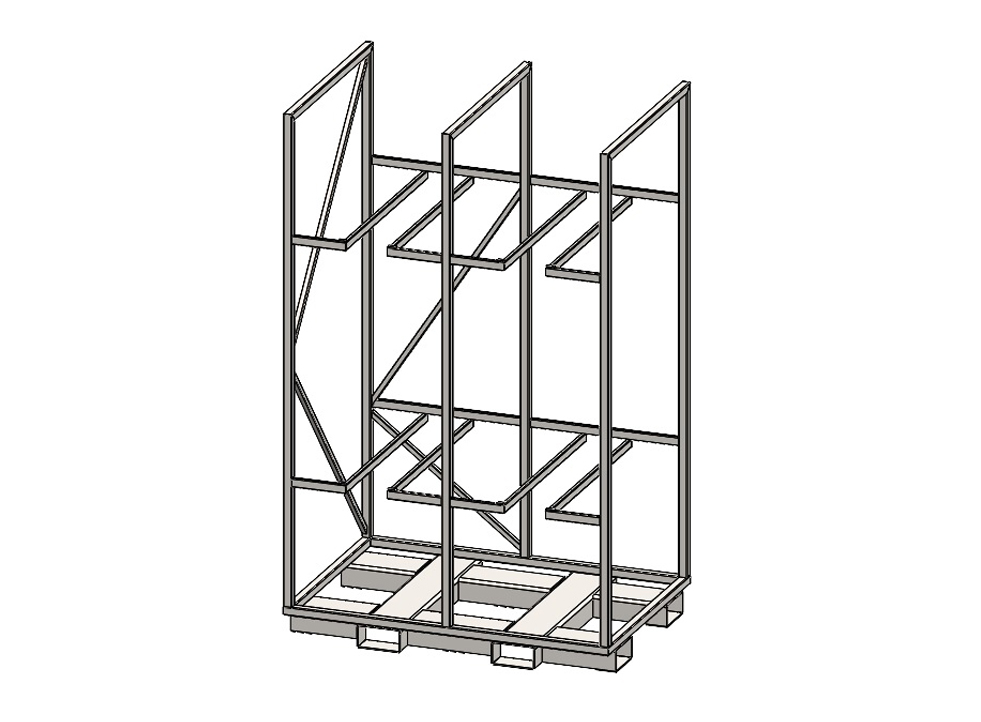

Storage solutions

From bespoke stillages to customised storage tables that are designed for the exact requirements

Loading platform

A bespoke platform designed for a very specific equipment handling project within water treatment

Rolling roads / chassis dynos

We are experts in the design for manufacture of rolling roads / chassis dynamometers used within the automotive industry

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.