Engineering design

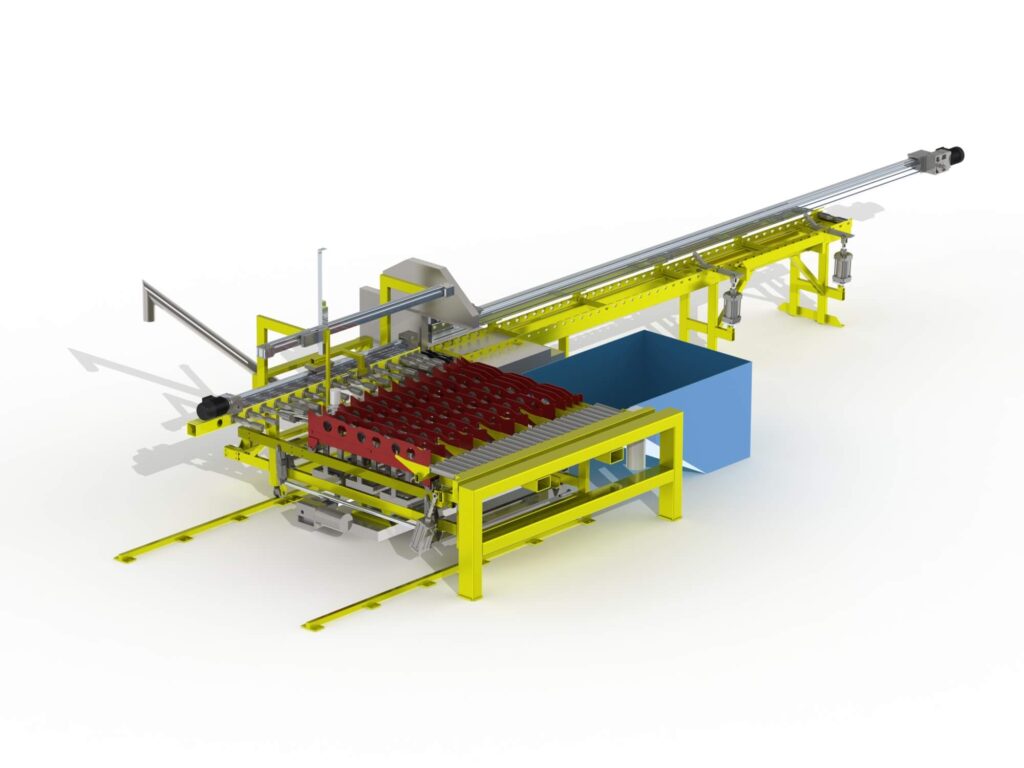

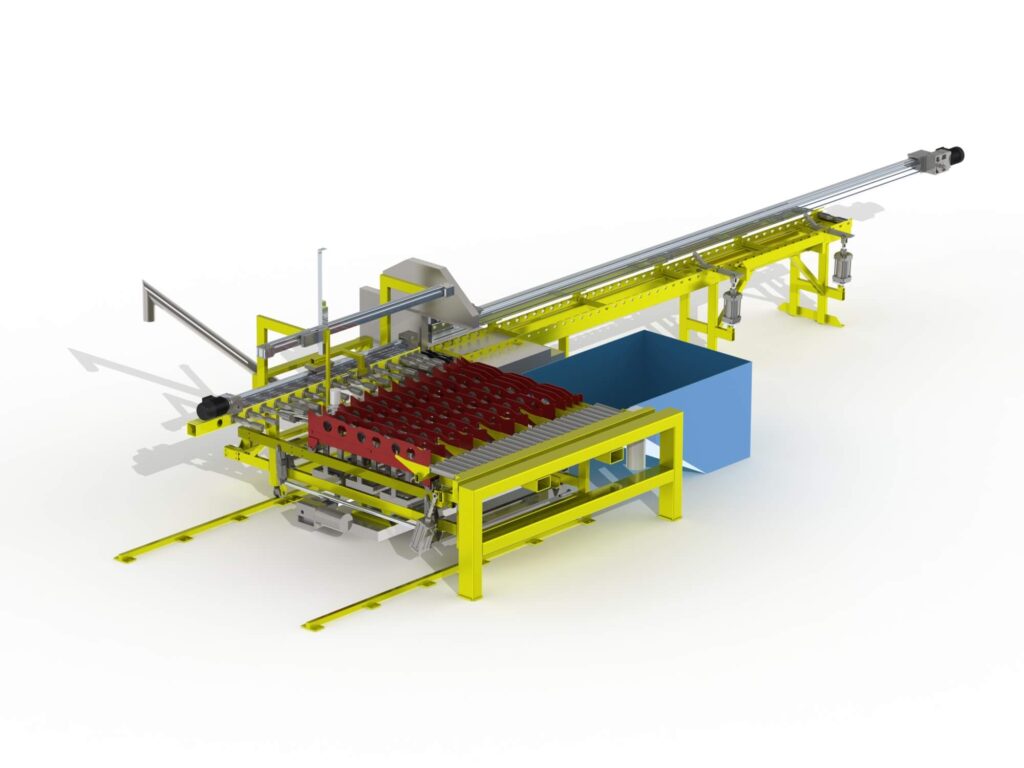

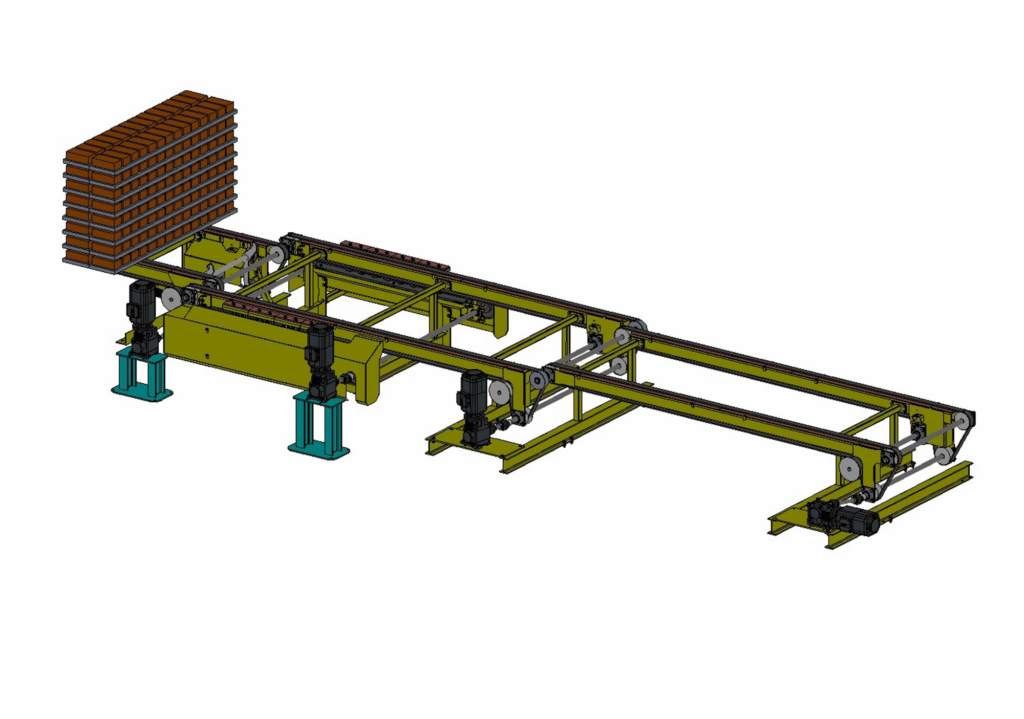

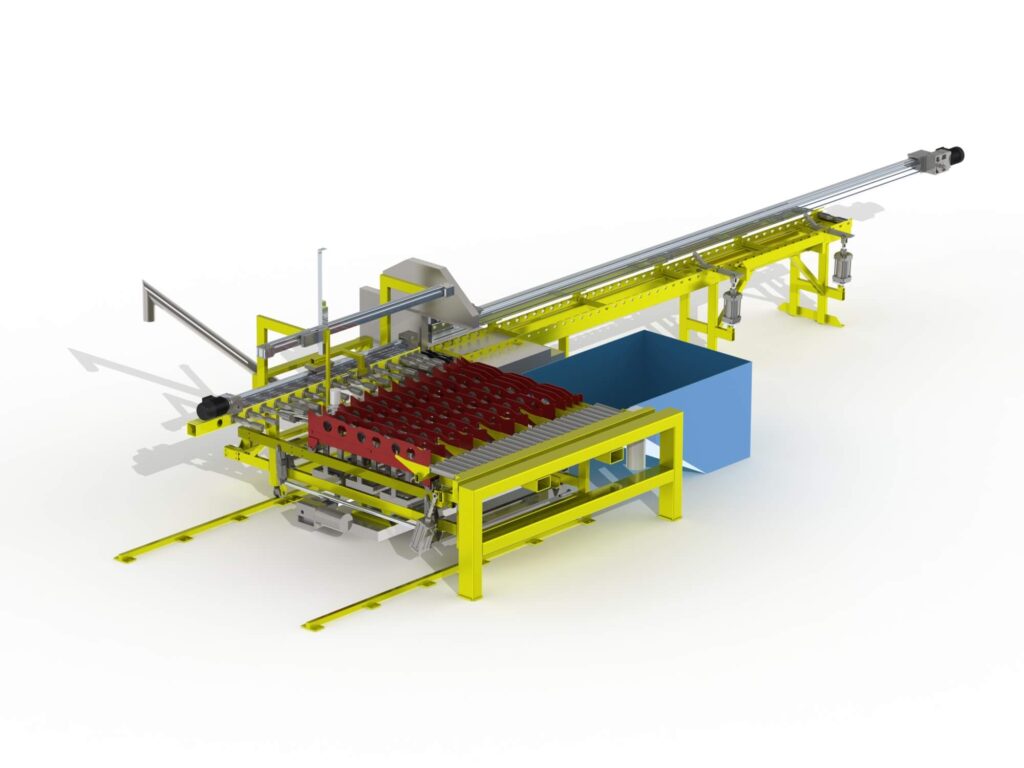

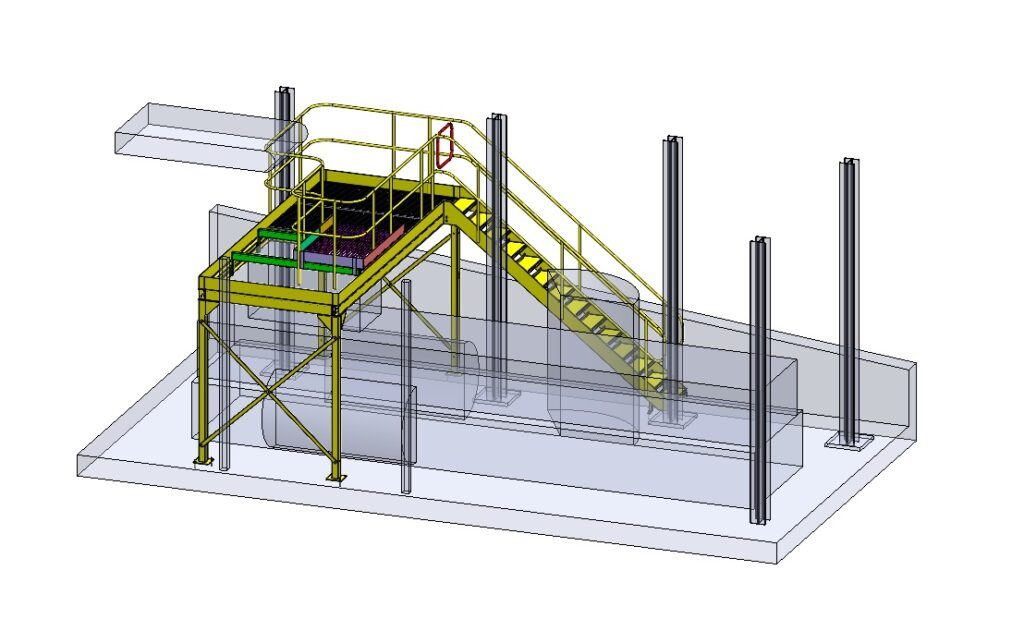

We’re exceptionally proud of the quality of our CAD drawings and models; they are completed to a very high standard and to ensure accuracy. One of our secret weapons for engineering design is that the manufacturing drawings we complete are easy to understand. That’s not us blowing our own trumpet, that’s the feedback from the manufacturing partners like the fabricators we work with.

Apexis Engineering start every project with a conversation.

It’s important that we understand the project brief, the setting of what you want us to design, the usage of the machinery and equipment and most importantly how the people onsite are using it so that everything is considered before we kick off.

We work in stages, sometimes you might only need one stage (a concept modelling for example) or you might need a reverse engineering project or perhaps you have a machine but no CAD for it. We’re flexible on how we work with you to deliver what you need.

Years of delivering engineering solutions

Projects delivered

Of all designs manufactured

Concept design

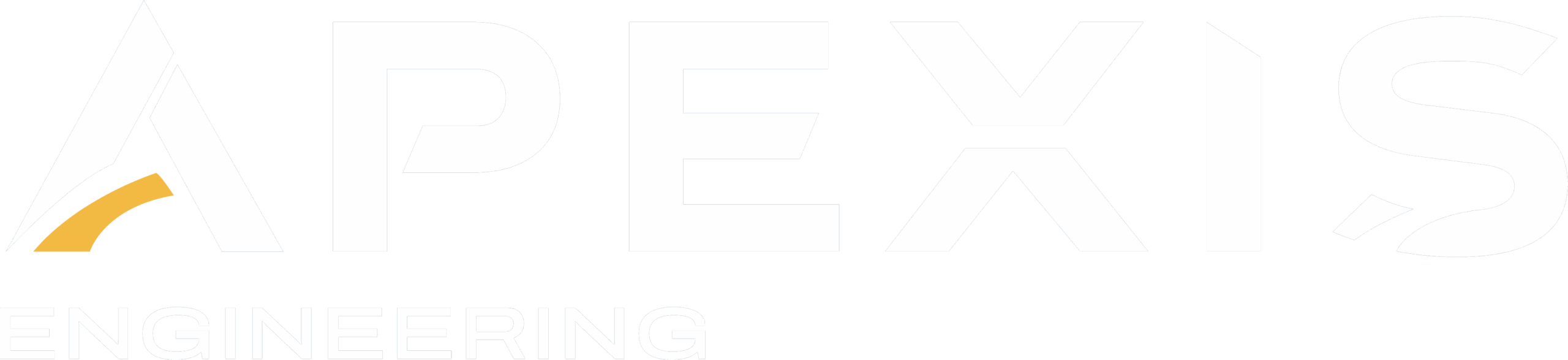

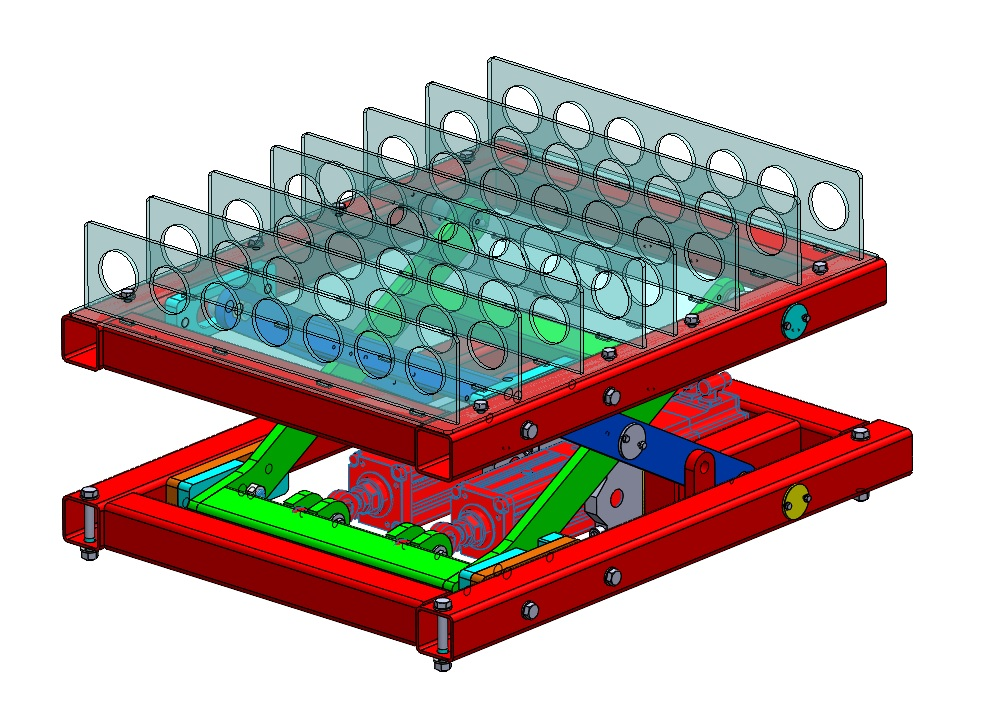

This is stage one of a full project and it’s where we provide all the options from the conversations and site survey. We’ll put our engineering thinking caps on and come up with what you need and present it back to you in a 3D model which provides great visualisation to progress the project

Having concepts created in CAD as 3D models lets design engineers prove out ideas digitally before anything is built, reducing risk and cost early in the project. 3D models provide clear, realistic visualisations that make it easier for stakeholders, fabricators, and installers to understand the design, spot clashes, and give meaningful feedback. They also allow rapid iteration, precise control of dimensions and interfaces, and direct downstream use for drawings, simulations, and CAM, which shortens lead times and improves manufacturing accuracy.

Apexis Engineering are happy to provide this as a one-off service too if you need a 3D CAD model for a concept but nothing further, we can help.

Detailed design

When Apexis Engineering move to this stage from concept everything is signed off and it’s an intensive process to compile a detailed design in CAD. Typically, our design engineers don’t like to be interrupted in this stage of the project and if you are wanting to change things then be warned – it’s going to get costly!

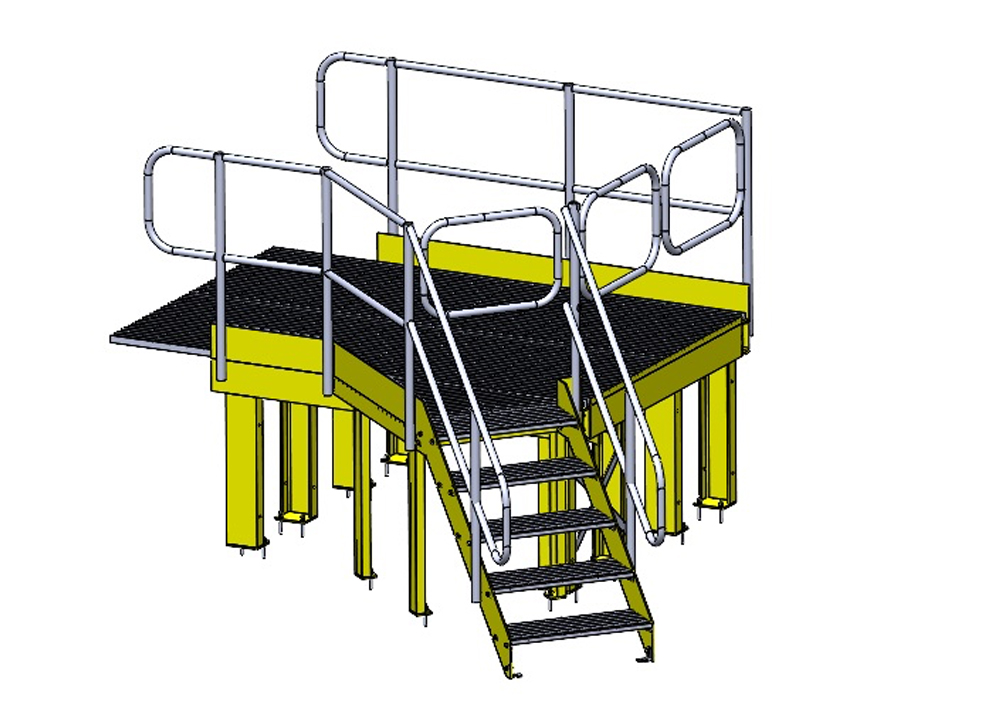

Detailed design transforms proven concepts into fully specified, manufacturable components by capturing every dimension, tolerance, material, and assembly requirement in precise 3D models. This stage bridges design intent and production reality, allowing us as design engineers to optimise part geometry for specific manufacturing methods, validate fits and clearances digitally, and generate complete drawing packs that fabricators can work from without guesswork. The result is faster handoffs to production, fewer errors and rework cycles, and direct integration with CAM systems for CNC programming, ensuring what is designed is exactly what gets built.

Here at Apexis Engineering the IP that is involved in this stage of a project is handed over to you, once you’ve paid your bill in full!

Manufacturing design

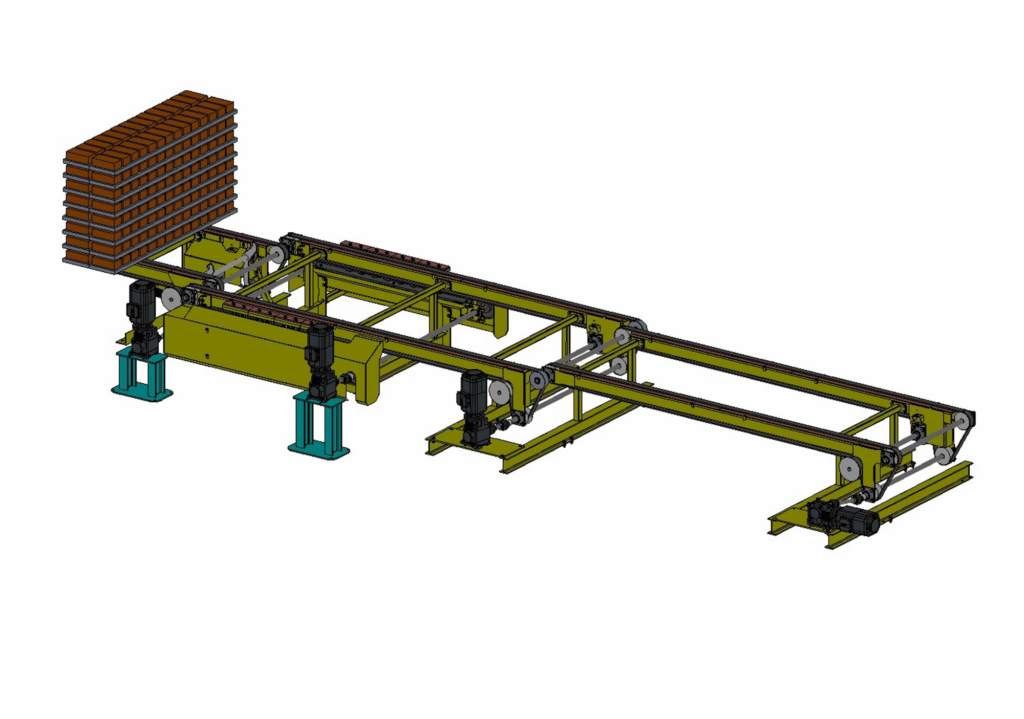

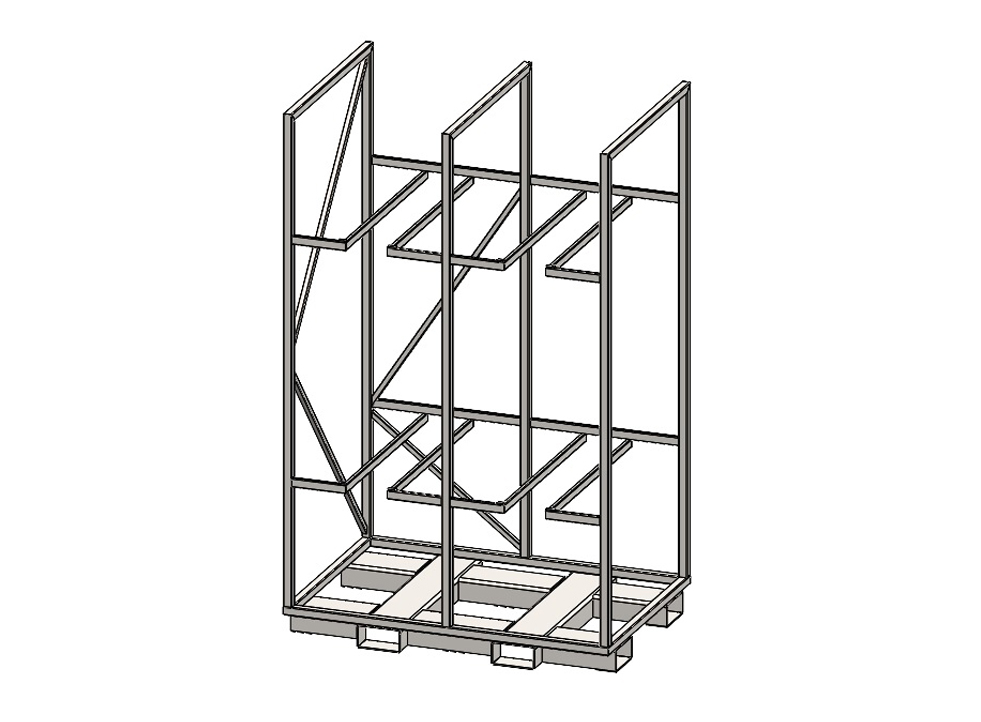

Also known as manufacturing packs at this stage when compiling in CAD we’ll be pulling everything together so we can make your design accurately and efficiently from a single, consistent source. Here at Apexis Engineering we are experts and will always deliver and outstanding manufacturing pack which typically includes fully detailed 3D models, dimensioned 2D drawings, cut lists and bills of materials, with every part clearly numbered and linked. It will also contain weldment and fabrication drawings, material and finish specifications, GA/assembly drawings with exploded views, and any critical tolerances or quality checks. For production, we’ll add DXF/NC profiles for laser or plasma cutting, hole and thread callouts, and clear notes on welding symbols, coatings, and packaging so there’s no guesswork on the shop floor.

You could say we are professionals when it comes to producing manufacturing packs, what we’d say is we produce world-class manufacturing designs. We say that because over 95% of all the designs we’ve produced have been made and are in use at sites across the world.

Value engineering

Here at Apexis Engineering we are specialists in value engineering machinery so that it’s:

- More profitable

- Quicker to assembly

- Uses fewer materials

- Needs less skilled labour

- More consistent

- Better functionality

- Easier to ship / install / commission

Our value engineering process on existing machinery is completed in CAD allowing our design engineers to strip out complexity, standardise parts, and re-think how everything goes together so it is easier and cheaper to build. By rebuilding legacy assemblies as accurate 3D models, it becomes possible to identify duplicate or near-duplicate components, rationalise fasteners and profiles, and redesign subassemblies for common tooling and repeatable build sequences. The result is shorter assembly times, less scope for error on the shop floor, reduced stock of spare parts, and a cleaner, more robust design that is easier to maintain and scale.

Reverse engineering

We often receive enquiries for undertaking a reverse engineering project where a business has a product without CAD or that needs redesigning for better usability or to be more competitive in the marketplace. Sometimes all we get is the bit of physical kit!

Reverse engineering is the process of carefully measuring and analysing an existing part, assembly, or machine to recreate it digitally and understand exactly how it works. It is especially valuable when original drawings or models are missing, parts are obsolete, or OEM spares are costly or have long lead times. Undertaking this process allows you to create compatible replacements without starting from scratch. By rebuilding a design in CAD, our design engineers can reproduce the original geometry but also improve materials, tolerances, and features to enhance performance, durability, and ease of manufacture. This helps extend the life of legacy equipment, reduce downtime and maintenance costs, and often uncover opportunities to standardise components or simplify future upgrades.

FAQs

What does the “concept design” stage involve?

In the concept stage, our design engineers take your problem or idea and turn it into clear 3D CAD concepts and layout options. The focus is on exploring different approaches, checking basic feasibility, and agreeing a direction before detailed work or fabrication costs are committed. We sometimes provide multiple options to solve your challenge at this stage depending on the project.

What is a manufacturing pack and why is it important?

The manufacturing pack is the complete set of information a fabricator needs to build your equipment accurately and efficiently. It typically includes 3D models, detailed drawings, cut lists, bills of materials, weld and fabrication details, and assembly drawings, so there is no ambiguity on the shop floor. Without a good manufacturing pack, you’re going to see lots of issues when your machine or equipment is made.

How do these stages reduce project risk?

Moving methodically from concept to detailed design to a robust manufacturing pack means issues are caught on screen instead of on site. This reduces rework, shortens installation time, and gives you a clear audit trail of decisions and specifications at every step. Apexis Engineering have proven our project process and are proud of the outputs at each stage.

Case studies

Scissor lift

Creating a robust piece of equipment that was a critical part of handling products coming off a production line

Storage solutions

From bespoke stillages to customised storage tables that are designed for the exact requirements

Loading platform

A bespoke platform designed for a very specific equipment handling project within water treatment

Rolling roads / chassis dynos

We are experts in the design for manufacture of rolling roads / chassis dynamometers used within the automotive industry

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.