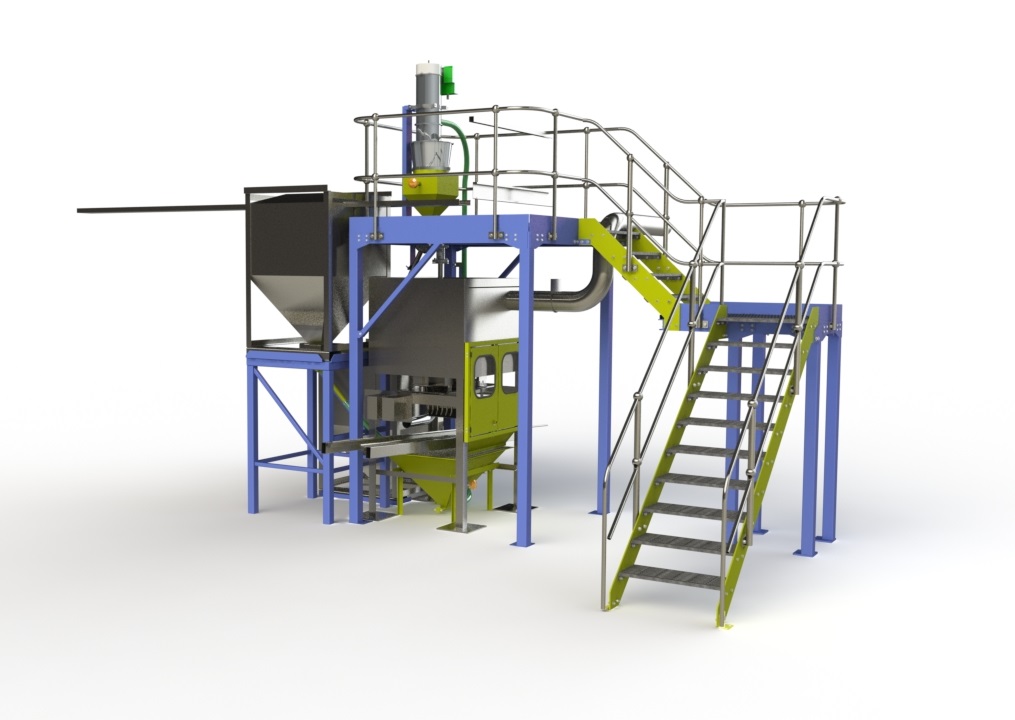

Granulate system

Apexis Engineering designed a granulate recovery plant for a leading roof tile manufacturer. The granulate pellets for the roof tiles were applied by hand originally, an ageing unreliable system was in place but major issues arose from it being difficult to maintain to material not landing properly meaning waste was high.

They required a replacement plant for an unreliable and difficult to maintain screw conveyor and bucket elevator. The identified solution for the client was a simple lean-phase pneumatic conveying system.

It was essential to remove the spillages and eliminate the hazards that were present in the existing set up. Spending time onsite enabled a comprehensive project brief to be compiled and measure up the plant location properly as well as ensure the right processes would be deployed.

Project outcomes included:

- Rapid clean down to minimise changeovers and reduce cross contamination

- Reduced leakages and spillages

- Safe and easy access for maintenance

- Installed with minimal downtime

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.