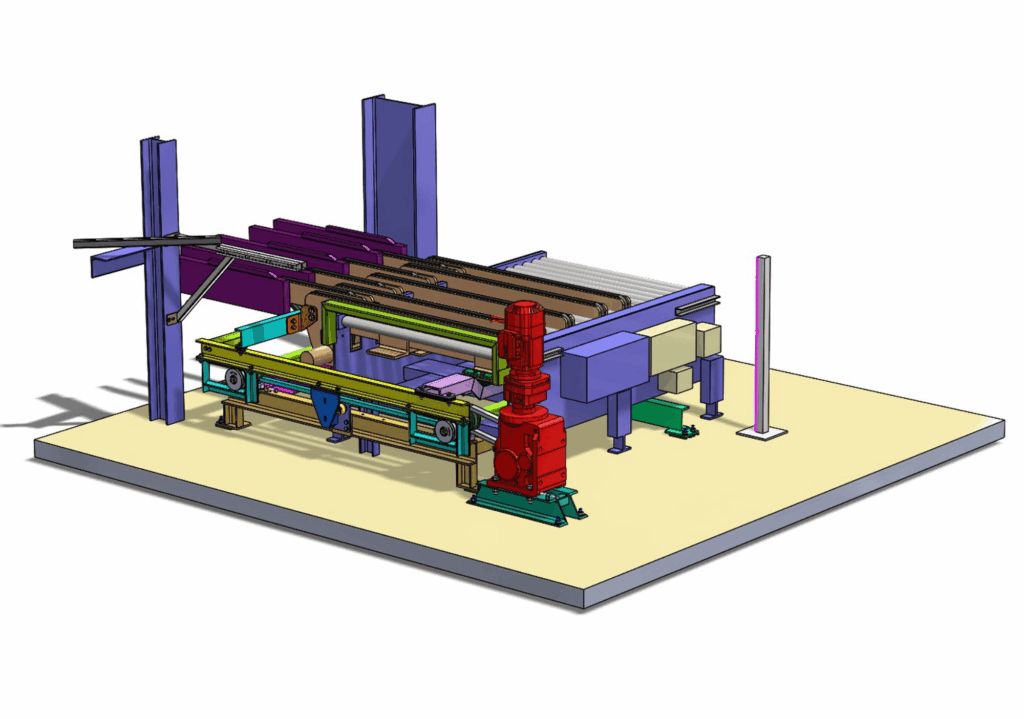

Lift and turn machine

A large construction product manufacturer required a lift and turn machine for packing of bricks. This machine needed to be part of a brick manufacturing plant that was operating for 12 to 18 hours per day 360 days per year.

The unit transports packs of bricks into a shrink-wrapping machine, raises them up so the wrapping extends under the base then turns the pack 90o before transporting them out of the factory.

The challenges included:

- Machine load: 12.5kN

- Space and packaging constraints

- Accurate, repeatable positioning for both height, rotation, and pack positioning: +/-1mm

- The dusty and dirty environment

- Provision for safe cleaning, inspection, and maintenance

- Installation within an eight-hour shift

Apexis Engineering provided a bespoke machine with compact linear servo actuators with holding brakes. The space restrictions prevented a single linear unit fitting, so an electronically matched pair provided enough force to lift the load through a scissor mechanism.

Servo drives were deployed for the other functions which allowed the position of the packs to be adjusted from outside of the guarded area which was useful for operators. Covers were included to prevent dust and debris falling into the mechanism. Maintenance lockout pins were provided to remove potential energy due to gravity.

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.