Have you heard of the 5Ps when it comes to planning? Well here at Apexis Engineering our process steps are all about ensuring project success.

Our Process

Stage 1: Concept

- We create multiple options to solve the challenge

- The site is surveyed to understand the workplace, the space, the operations, the processes and everything else

OR

- We undertake a design review of your concept

Everything needs to be signed off on the blocky CAD model we’ll present to show the concept options or review.

Stage 2: Detailed design

The concept model will be progressed with all the detailing that’s required in a design for manufacture project.

During this stage CAD will be updated and shared at certain points for decisions or discussions using a 3D model

Stage 3: Manufacturing pack

The detailed design will be taken to create a manufacturing pack which will provide:

- DXF / DWGs or PDF drawings which will include:

- Bill of materials (BOMs)

- Cut lists

- Weld details

- Machining details

Stage 4: Manufacturing

Who better to make your bespoke machinery, customised equipment or tailor-made plant than the people who designed it?

Apexis Engineering work with strategic partners and source all of the parts needed to take away your headache of getting things made.

Everything we manufacture is with trusted partners whose quality is exceptional.

Stage 5: Assembly and commissioning

Your equipment or machinery will be assembled and commissioned here at Apexis Engineering.

Or our team can be there on your site to commission what we’ve made; especially if it is plug and play style machinery or equipment.

Stage 6: Installation

The final stage of delivery for your project where we can:

- Provide part installation (i.e. your team connects to PLC for example)

- Full installation of equipment or machinery

Stage 1: Concept

- We create multiple options to solve the challenge

- The site is surveyed to understand the workplace, the space, the operations, the processes and everything else

OR

- We undertake a design review of your concept

Everything needs to be signed off on the blocky CAD model we’ll present to show the concept options or review.

Stage 2: Detailed design

The concept model will be progressed with all the detailing that’s required in a design for manufacture project.

During this stage CAD will be updated and shared at certain points for decisions or discussions using a 3D model.

Stage 3: Manufacturing pack

The detailed design will be taken to create a manufacturing pack which will provide:

- DXF / DWGs or PDF drawings which will include:

- Bill of materials (BOMs)

- Cut lists

- Weld details

- Machining details

Stage 4: Manufacturing

Who better to make your bespoke machinery, customised equipment or tailor-made plant than the people who designed it?

Apexis Engineering work with strategic partners and source all of the parts needed to take away your headache of getting things made.

Everything we manufacture is with trusted partners whose quality is exceptional.

Stage 5: Assembly and commissioning

Your equipment or machinery will be assembled and commissioned here at Apexis Engineering.

Or our team can be there on your site to commission what we’ve made; especially if it is plug and play style machinery or equipment.

Stage 6: Installation

The final stage of delivery for your project where we can:

- Provide part installation (i.e. your team connects to PLC for example)

- Full installation of equipment or machinery

Case studies

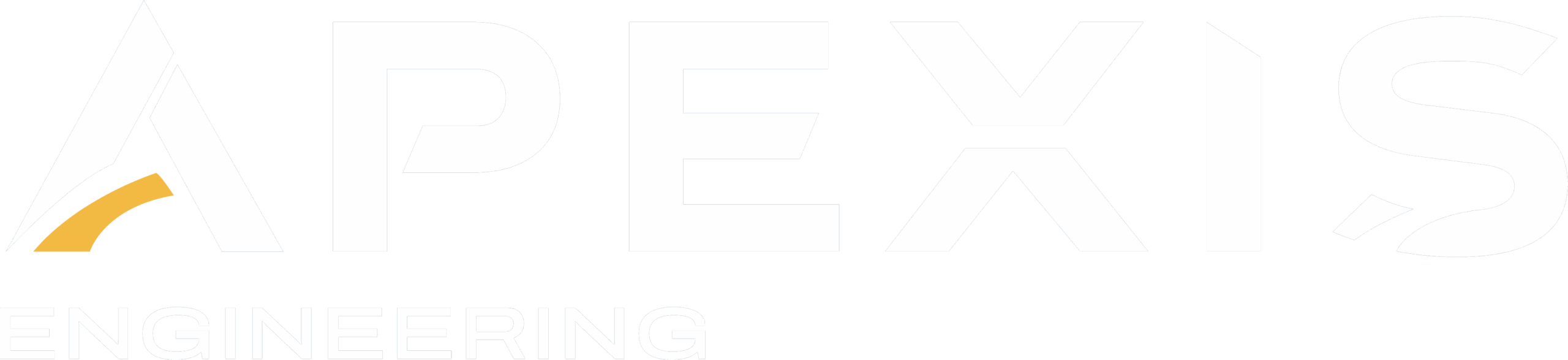

Scissor lift

Creating a robust piece of equipment that was a critical part of handling products coming off a production line

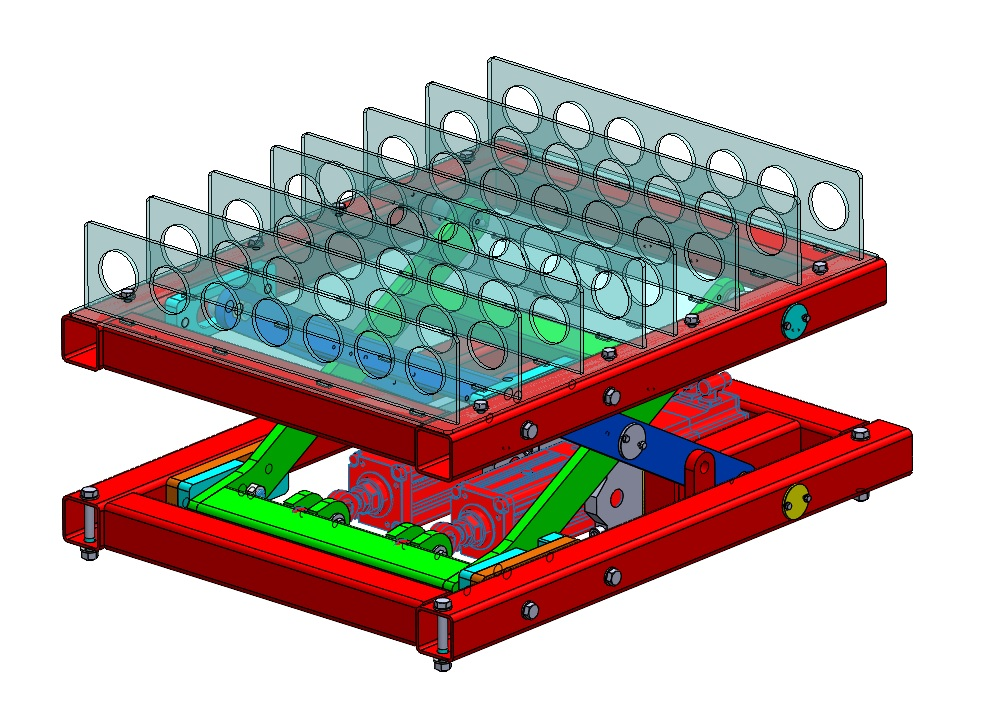

Storage solutions

From bespoke stillages to customised storage tables that are designed for the exact requirements

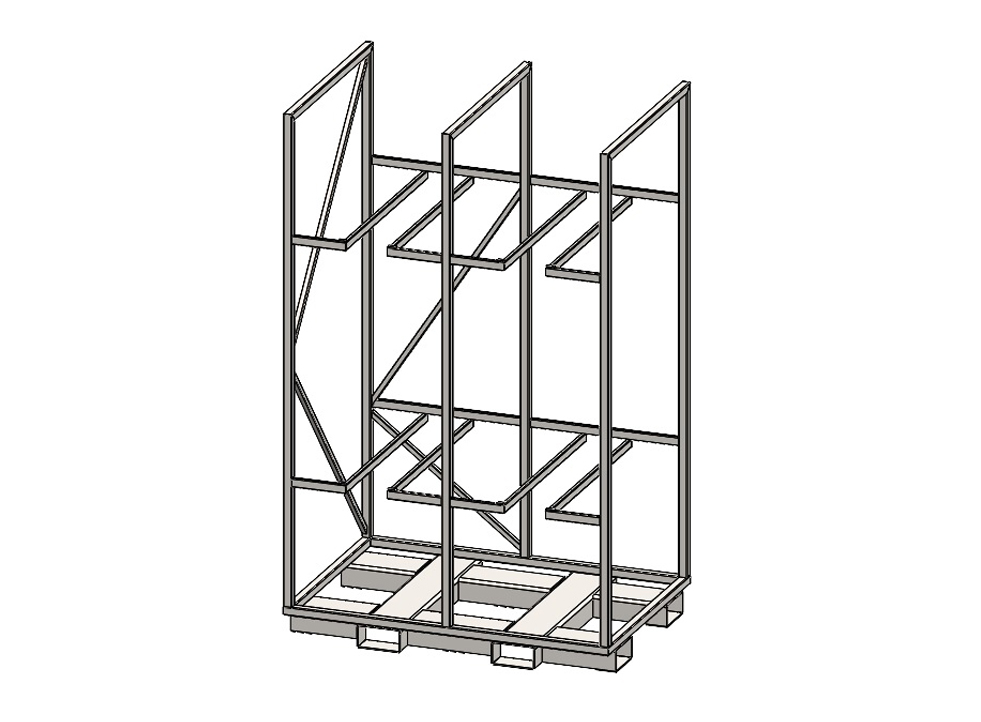

Loading platform

A bespoke platform designed for a very specific equipment handling project within water treatment

Rolling roads / chassis dynos

We are experts in the design for manufacture of rolling roads / chassis dynamometers used within the automotive industry

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.