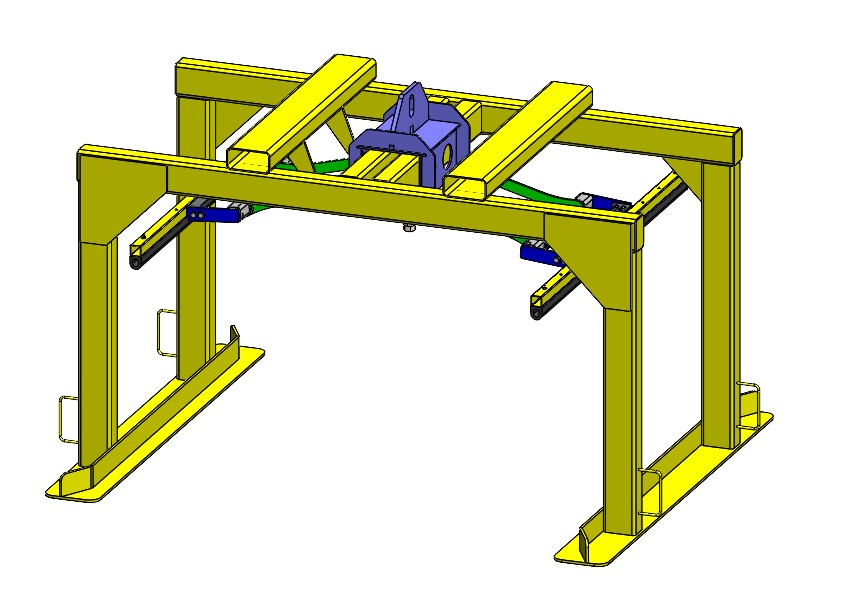

Pallet lifter

Apexis Engineering have designed and supplied a wide range of customised equipment into industrial workplaces that have improved the safety of lifting. For this specific lifting equipment project, a bespoke pallet lifter for the brick industry, we provided significant benefits in terms of safety and operational effectiveness.

The project brief provided the details on our client’s very clear challenge which was how to extract 18,000 pallets from an old system and insert them into the new one both safely and efficiently. The pallets are made from galvanised steel; each weighed 12kg and measured 2200 x 260 x 35mm. Wet bricks are placed onto the pallets during the manufacturing process. These were then transported to the dryers, after which the dried bricks are removed ready for firing and the pallets returned to go around the loop again. Stacks of pallets were 2600mm high and weighed over 5 tonnes which were held in a buffer store. Our design process took into consideration the data above with the additional considerations on operator usage, moveability of the pallet lifter around the site and installation process.

The lifting equipment was a major requirement for this larger scale industrial project and was specified as a single use item; we were pleased that our client chose to use it more regularly by adopting the lifter for when pallets wear out, due to the design effectiveness, robustness and mobility the lifter could be used long term to load new replacement pallets into the new system.

Apexis Engineering carried out the manufacture, testing, certification and installation of this lifting equipment.

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.