Plug and play plant

A brick factory required plug and play machinery that would provide specific actions to manufacture their product range for an existing line. Apexis Engineering created a concept, delivered detailed design and manufacturing packs, manufactured and assembled the machinery and were on site for the commissioning.

These machines replaced ones that were not performing on the production lines; 4 were required.

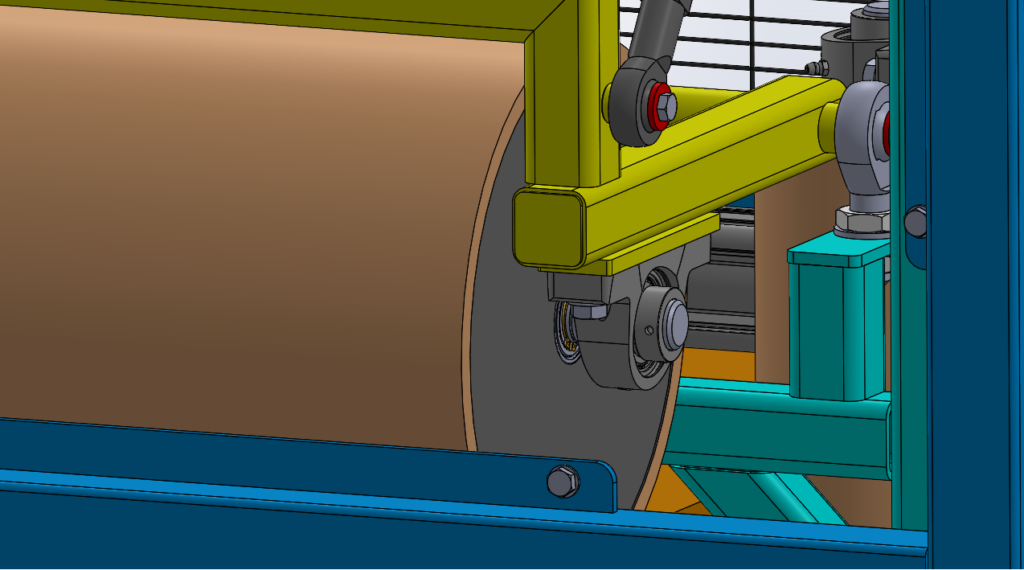

We won’t give you all the inside information on this machinery, but the clever bits were how the rollers were controlled in such a way that could accommodate the variation in the raw material extrusion. The rollers could adapt to whatever the height or width of the extrusion and still complete the markings required to meet the quality requirements for the bricks.

Today the machinery is doing what it is supposed to do to make a final product that is of high quality for the building industry and what’s more the maintenance teams liked how easy things were to install, maintain and see!

Project outcomes:

- Easy to install and maintain

- Consistent quality

- Higher throughput

- Safer and easier to use for operators

In fact, you could call us ace problem solvers for manufacturers and OEMs who need a partner that delivers on time, within budget and in full. If it’s got our name on it you can guarantee we’ve done the best job possible for you and your team. Whatever your project or requirement here at Apexis Engineering we make it happen.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.