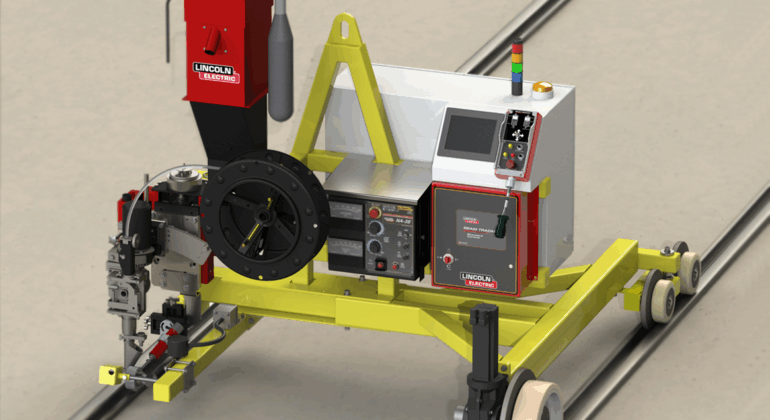

Does bespoke machinery and custom equipment help achieve efficiency, flexibility and genuine competitive advantage?

The manufacturing landscape is evolving, market demands shift quickly, competition intensifies from overseas and then things all shift again in the current operating environment. This article demonstrates how you can deploy bespoke machinery and custom equipment to push your processing into a format that helps you achieve what’s needed to increase your competitive advantage. That could be increasing throughput, introducing new processes, improving quality, changing a process, removing complexity or making it easier to maintain to reduce downtime.

Why bespoke?

Off the shelf machinery and equipment often fail to meet the demands of complex production environments; whether that’s because they don’t understand that your operating environment means unsealed bearings are a no go or there is a lack of understanding about the quality of products you are manufacturing. There’s been times when we’ve been bought in to hear that equipment has been delivered and it’s not fit for purpose, or it doesn’t work in the space allocated to the machinery. We could give you lots of examples in this area.

By deploying a project with Apexis Engineering for bespoke machinery or custom equipment you are choosing a partner than managers the entire lifecycle – from design to installation. There’s no multiple vendors to manage just a single supplier approach which delivers you an effective solution.

Full accountability

By managing your project from end-to-end communication becomes clearer and more direct. There’s no need to relay your technical requirements to anyone other than Apexis Engineering which reduces misunderstandings, speeds up decision making and ensures that nothing gets lost in translation.

Centralising responsibility for your mechanical engineering project with Apexis Engineering means clear accountability. We will make it happen.

Optimised for your operations

When you appoint Apexis Engineering as your partner to deliver your project in full the first communication will be centred around a site survey. Yes we might have visited a few times, but this survey will be comprehensive and is the starting point to getting the project right.

During a site survey our engineers will consider in full:

- Measure and assess the working environment and space constraints

- Understand how the operators will use the equipment day to day

- Find out the quality information in full

- Identify the hazards, obstructions or operational challenges

- Collaborate directly with operators to ensure everything we design is user friendly

This hands on approach guarantees that our solutions are practical in your real work operating environment and not just on CAD where we can lift and rotate a heavy piece of metal at the click of a mouse button!

Key considerations

Apexis Engineering will consider several elements, not just the legislative things like PUWER to ensure your equipment is safe and suitable (we always stick to the legislation first!) but als other things like your operating environment.

As we said earlier, if you are creating or using dusty material then it’s pointless having machinery that is going to quickly stop working due to dust ingress. We’ll work towards ensuring there’s no exposure to dust using simple options like covers and seals that are right for the processing environment.

Another area that Apexis Engineering really stand out is considering your team’s requirements for example if you need some machinery that needs adjusting is that with one operator or more and if more how practical is that for your shift and setting? Similarly, when it comes to maintenance, we’ll ensure that everything is simple to install, easy to maintain and there are spares available for your machinery.

If things need considering, we’ll do that at the beginning of the project; the concept(s) we provide will take all the key considerations into account.

Cost transparency

A single supplier model offers clearer cost breakdowns and better budget controls. And when it comes to cost transparency there won’t be any surprises like having to upgrade your electricity to accommodate new machinery or add an extra layer of guards due to poor safety or even worse replacing the machinery because it simply doesn’t work.

Due to the process Apexis Engineering follows you will get an expected budget cost at the beginning of the project with a real cost for the first step (whether that’s concept or detailed design). Our process is designed to give you the costs in a controlled way.

Supporting manufacturing excellence

By partnering with us you are choosing a true bespoke machinery design and manufacturing specialist, manufacturers can also tap into deep local knowledge and agile support, tailored to the specific needs of your industry segment and regulatory standards. We make it happen and are committed to your long-term success by fostering sustained innovation and exceptional service quality to every client for every project.