Importance of detailed design for bespoke machinery

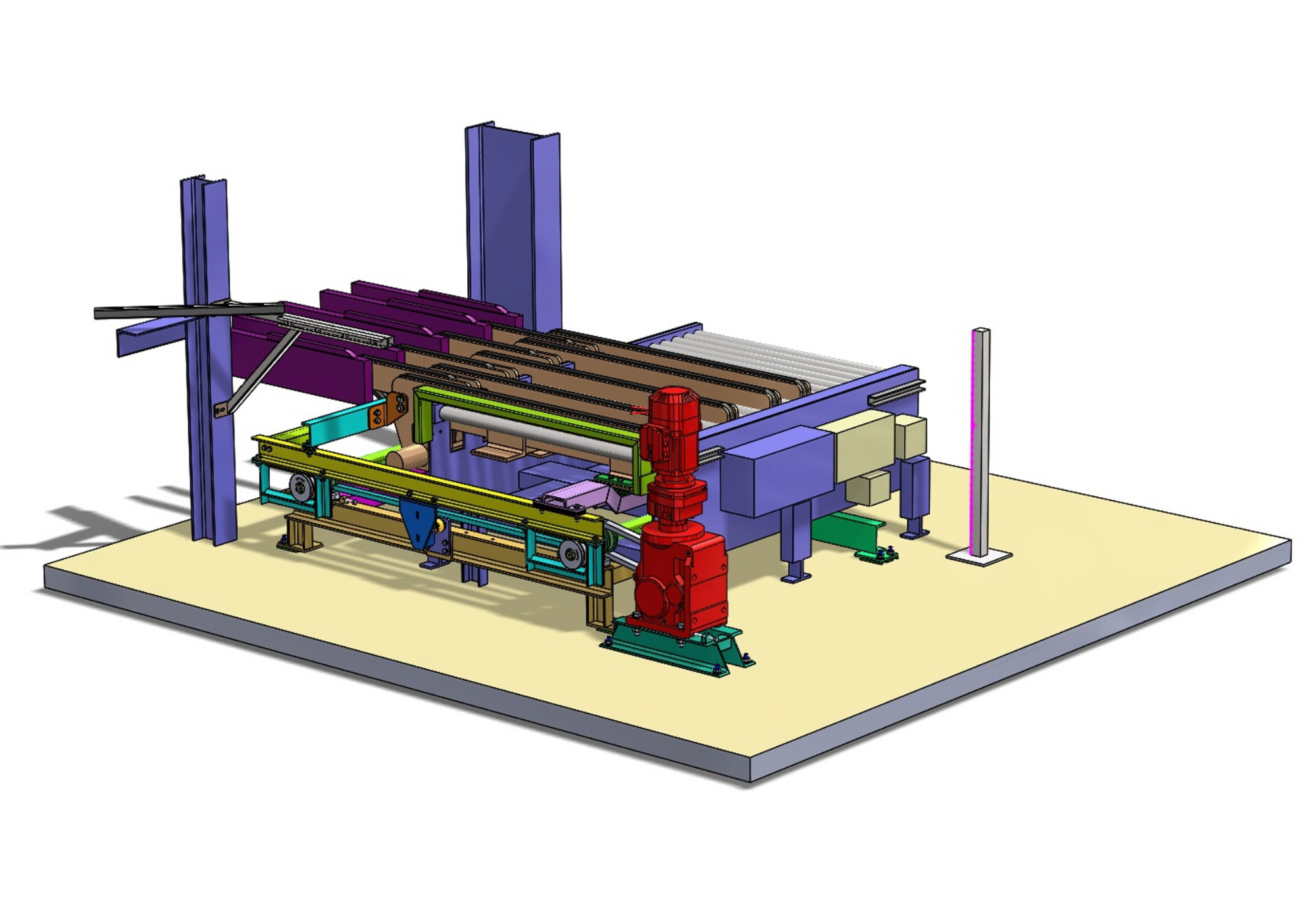

In this expert log we’ll walk you through the importance of high quality detailed design and manufacturing pack creation for bespoke machinery.

Detailed manufacturing drawings are pivotal to producing machinery that fits together seamlessly and operates efficiently on processing lines. High-quality design documentation is the key link between ideas and reality, ensuring every component aligns and functions as intended during assembly, commissioning and installation.

What’s the role of detailed drawings?

- Drawings clarify design intent, specifications, and dimensions, acting as the “blueprint” for every step of manufacturing.

- They document materials, tolerances, and assembly instructions to guarantee shared understanding amongst designers, engineers, and production teams.

- Accurate drawings prevent miscommunication, costly errors, and delays from mismatches and assembly issues.

Achieving success with high quality detailed drawings

- Tolerances and fit details in drawings directly impact how parts assemble; overlooking these can cause misalignment, rattling, or outright failure during installation.

- Technical drawings guide the fabricator or machinist’s work, leading to parts that meet quality and functional benchmarks on the first attempt, reducing waste from rework or unusable parts.

Efficiency, quality, and cost control

- Well-crafted manufacturing drawings minimise time spent troubleshooting unclear specifications, supporting smooth and efficient production of bespoke machinery.

- Accurate documentation improves estimates for materials and labour, controlling costs and reducing risk throughout the project.

- Detailed drawings empower quality control processes, enabling reliable inspection and verification that final products meet all requirements for your custom machine.

What’s the role of detailed drawings?

Apexis Engineering leverages meticulous attention to design detail as a hallmark of reliability and quality. Every project for bespoke machinery benefits from transparent communication, team collaboration, and proactive review of designs for manufacturability and assembly. This diligence is core to our promise – “we make it happen” by ensuring smooth transitions from concept to finished machinery and delivering outcomes that work precisely where it matters most.

In short, detailed manufacturing drawings are not just a paperwork exercise; they are the foundation that makes great outcomes possible for machinery on demanding processing lines.

Get in touch with Apexis today to see if we can make your project happen

We’ve designed and manufactured material processing machinery, rolling roads, shredding machines, battery recycling processes, mobile equipment, lifting jigs, electronic product recycling machines, factory in a box and shredding machines. The best way to understand if we can help with your project is to get in touch.